Description of the device

4

—

English

Servimat M/L — 28.01.2021

3.5

Inadmissible operating conditions

The device is not suitable for the following applications:

•

Outdoor operation.

•

For use with mineral oils.

•

For use with flammable media.

•

For use with distilled water.

Note!

It is not permitted to make any modifications to the hydraulic system or

the circuitry.

3.6

Residual risks

This device has been manufactured to the current state of the art. However,

some residual risk cannot be excluded.

CAUTION

Risk of burns on hot surfaces

Hot surfaces in heating systems can cause burns to the skin.

•

Wear protective gloves.

•

Please place appropriate warning signs in the vicinity of the device.

CAUTION

Risk of injury due to pressurised liquid

If installation, removal or maintenance work is not carried out correctly, there is a

risk of burns and other injuries at the connection points, if pressurised hot water

or hot steam suddenly escapes.

•

Ensure proper installation, removal or maintenance work.

•

Ensure that the system is de-pressurised before performing installation,

removal or maintenance work at the connection points.

CAUTION

Risk of injury due to heavy device weight

The device weight may cause physical injury or accidents.

•

If necessary, work with a second person during assembly or disassembly.

CAUTION

Risk of injury when upon coming into contact with glycol containing water

Contact with glycol containing water in plant systems for cooling circuits can

result in irritation of the skin and eyes.

–

Use personal protective equipment (safety clothing, gloves and goggles,

for example).

4

Description of the device

4.1

Description

The Servimat is a pump-controlled pressure maintaining, make-up and

degassing station for heating and cooling water systems. The Servimat is

essentially a control unit with pump, vacuum spray pipe and at least one

expansion vessel. The expansion vessel is fitted with a membrane to divide the

vessel into an air space and a water space. preventing the ingress of atmospheric

oxygen into the expansion water.

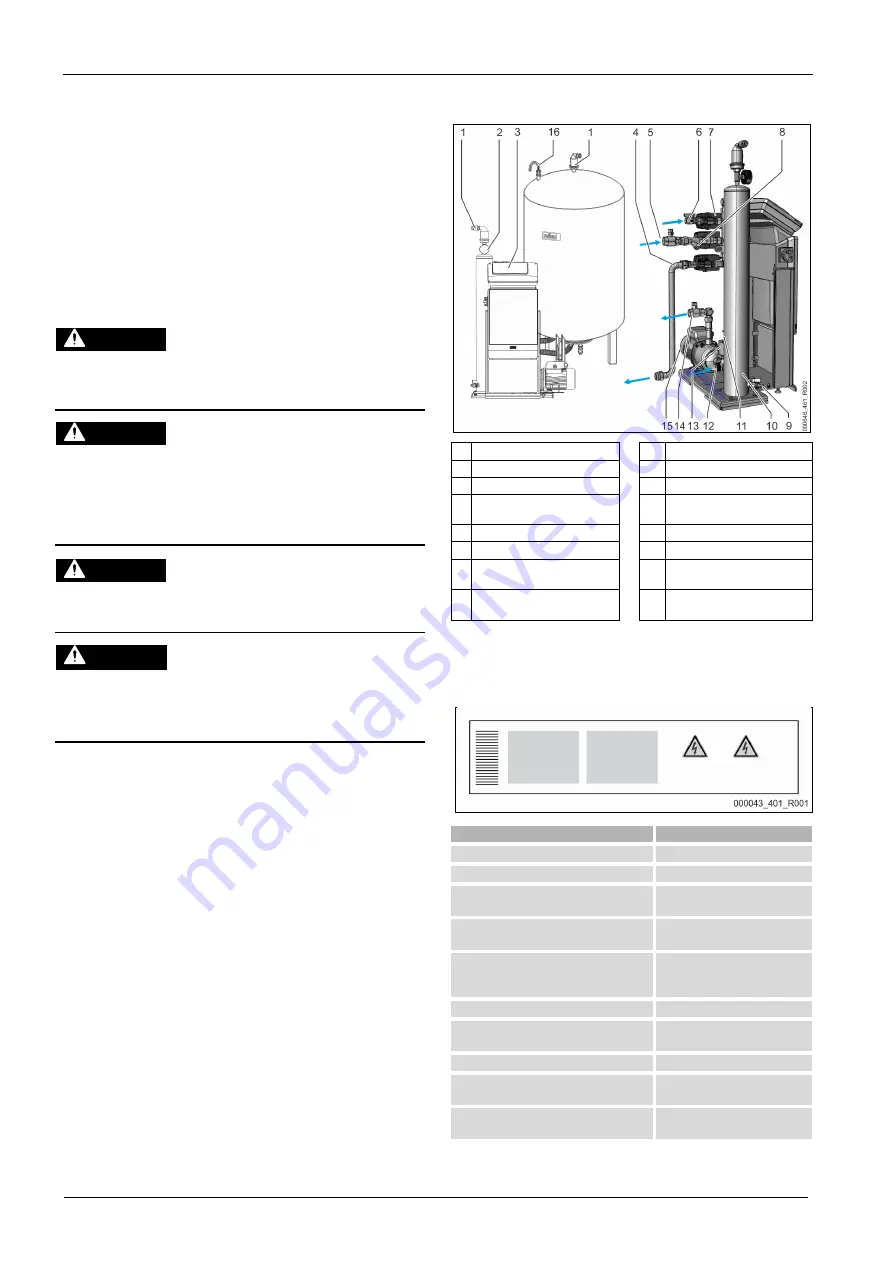

4.2

Overview

1 "DV" degassing valve

9

"FD" feed and drain cock

2 "PI" vacuum gauge

10 "VT" vacuum spray pipe

3 Control Touch controller

11 Insufficient water switch

4 Inlet to the expansion vessel

12 Connection from the expansion

vessel

5 Gas-rich water inlet

13 3-way motorized ball valve

6 Make-up connection

14 Degassed water outlet

7 2-way motorized ball valve (in

total 3x)

15

“PU” horizontal pump

8

“ST” dirt trap

16

“VE” pressure compensation

elbow

4.3

Identification

The nameplate provides information about the manufacturer, the year of

manufacture, the manufacturing number and the technical data.

Information on the type plate

Meaning

Type

Device name

Serial No.

Serial number

min. / max. allowable pressure P

Minimum/maximum permissible

pressure

max. continuous operating temperature

Maximum temperature for

continuous operation

min. / max. allowable temperature / flow

temperature TS

Minimum / maximum permissible

temperature / TS flow

temperature

Year built

Year of manufacture

min. operating pressure set up on shop floor Factory set minimum operating

pressure

at site

Set minimum operating pressure

max. pressure saftey valve factory - aline

Factory set actuating pressure of

the safety valve

at site

Set actuating pressure of the

safety valve