7

INSTALLATION AND ELECTRICAL CONNECTIONS

+

The AD SR2 safety interface must be installed in an environment with at least

IP54 protection.

+

The voltage supplied to the AD SR2 interface must be of the FELV (Functional

Extra Low Voltage) 24VDC

±±

20% type.

+

During installation, take care not to short-circuit terminals 7, 8, 10 and 11 on

the AD SR2 interface.

+

If connecting one barrier only, bring inputs that are not used (8 and 11)

to +24VDC.

The safety switch.

The system moves to

BREAK

status (output relays open) when the

safety switch

(e.g. emergency pushbutton, safety limit switch)

,

connected as illustrated in the electrical diagrams on pages 4, 5, 6,

is

opened.

The switch must respond to the following specifications:

•

2 N/C contact blocks connected mechanically.

•

Release action to control contact opening.

•

There must never be more than a 500msec delay between

both contacts in the switch closing; if that is not the case, the

interface moves to

FAIL.

The interface can only restart

(GUARD)

after resetting the switch (with

the barrier clear).

+

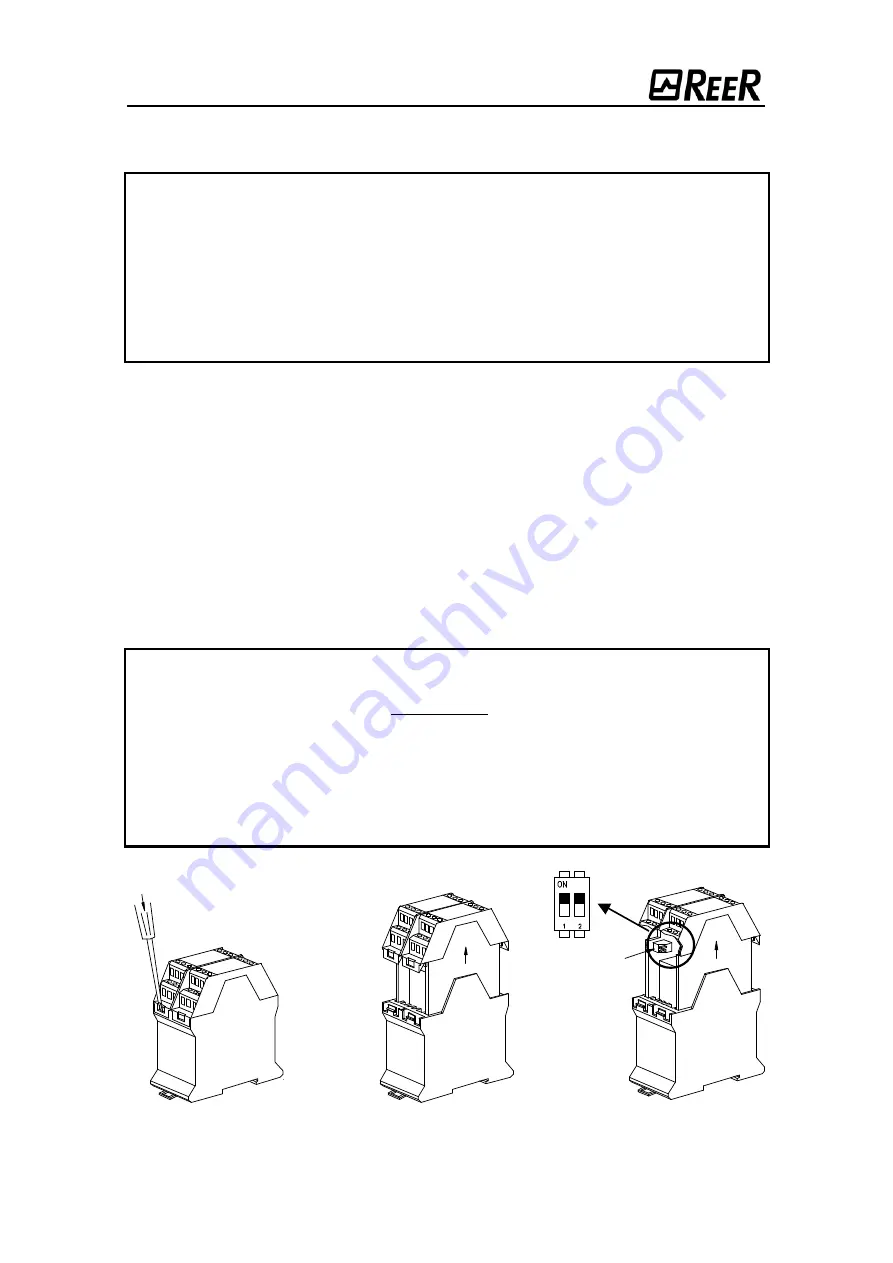

Should risk analysis regarding dangerous machinery authorize the use of a

safety switch with ONLY 1 N/C CONTACT (e.g. terminal 9 connected to +24VDC

or terminal 12 earthed), set both sections of the dip-switch (1) to ON (figure 5).

In that case, the test circuit for that specific safety switch will no longer

conform to EN 954-1 type 4.

+

If using a safety switch with ONLY 1 N/C CONTACT, terminal 9 must be used

(to +24VDC). Terminal 12 must be left open.

+

If the safety switch is not used, connect terminal 9 to +24VDC and terminal 12

to 0Vdc (dip-switch to OFF).

Figure 5

(1)

(PRESS LIGHTLY ON ALL

FOUR HOOKED COUPLINGS)

Summary of Contents for AD SR2

Page 2: ...2...