HIDEAWAY

ACTIVE SENSOR-FLUSH URINAL

Plumbers, please ensure a copy of the installation

instructions is left with the end user for future reference

HIDEAWAY

ACTIVE SENSOR-FLUSH URINAL

2.0

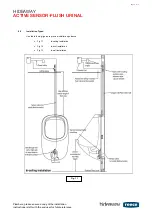

Rough in wall preparation:

Note:

All plumbing installation work has to be carried out in accordance with AS/NZS 3500.

Installation requirements may vary, please check with your local authority.

1. Determine mounting height of urinal based on recommended height to front edge (610mm)

2. Fit timber noggin into wall cavity to support urinal mounting brackets (Fig. 3)

3. Fit 20mm copper inlet pipe supported rigidly in wall allowing at least 30mm proud of finished wall and remove

burr from pipe end (Fig. 4). The flush pipe should be installed without offsets.

IMPORTANT:

Accuracy is required to maintain 495mm centre distance between inlet and outlet

4. Trap outlet seal fits straight into the inside of 50mm DWV PVC pipe

5. Minimum 20mm water supply to this urinal is required as per AS/ NZS 3500

6. Install flexible electrical conduit (32mm minimum size, not supplied) free of kinks for sensor extension

cable (Fig. 4)

7. Fit single 240 volt 10 amp GPO for transformer/power supply unit adjacent to proposed location of controller

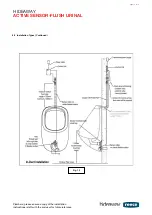

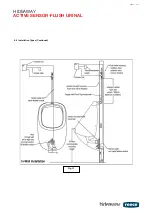

3.0

Control Unit Connection:

1. Ensure rough in wall details have been completed first as detailed in Figs. 3 and 4

2. Flush the water lines

3. Assemble flush valve components (Fig. 2) following directional arrow on solenoid valve body

during assembly

4. Install flush valve as required in-ceiling (Fig.11), in-duct (Fig. 12) or in-wall (Fig. 13)

5. Flush valve must be installed in the vertical position with the isolation valve closed

6. Connect flush valve to 20mm copper flush pipe using olive fitting supplied

7. Connect water supply to flush valve (1/2” BSP male inlet)

8. Peel off tape backing on Velcro strip to mount control unit directly into position

9. Make connection from flush valve to control unit using 1500mm solenoid valve cable.

NOTE:

Care must be taken to align pins inside each male connector with holes in female connector

before

pushing connectors together to prevent pins being bent.

10. Make connection of sensor cable to control unit.

11. Route sensor cable through flexible conduit and 100mm out through wall.

Fig. 3

Fig. 4

page 3 of 16