Jabłonna

-

Majątek 12

23-

114 Jabłonna

NIP: 712-254-67-61

tel. 81-565-71-71, fax 81-470-93-67, [email protected], www.phu-szczepan.pl, redats.pl

The EC Declaration of Conformity

CE-21

P.H.U. SZCZEPAN

Wyposażenie Wulkanizacji i Warsztatów

Jabłonna

-

Majątek 12

23-

114 Jabłonna

As an authorized representative of the manufacturer:

Safe Automotive Maintenance Equipment (Taicang) Co., Ltd.

No. 6, Binyang Road, Taicang Port Develop Zone, Jiangsu P.R. China

Product:

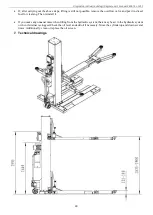

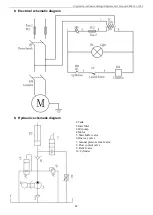

Mobile one-post hydraulic lift

Model: L-121F (SF-M2500)

Serial number:…………………………

Under the sole responsibility, we declare that the product is in conformity with:

EC Certificate, number

CE-C-0220-19-21-04-5A

issued on 2019.05.30 by Notified Body for Machinery Directive

CCQS UK Ltd.,5 Harbour Exchange Square, London, E14 9GE, UK

The product complies with the essential requirements of the:

2006/42/EC Directive

as well as the detailed requirements specified in harmonized standards of:

EN 12100:2010, EN 1493:2010, EN 60204-1:2006/AC:2010

This Declaration is a basis for applying the CE mark on the product.

This Declaration relates exclusively to the machinery in the state in which it was placed on the market, and excludes

components which are added and/or operations carried out subsequently by the final user.

Technical documentation is available at

: PHU SZCZEPAN Wyposażenie Wulkanizacji i Warsztatów, Jabłonna

Majątek 12; 23

-

114 Jabłonna, Poland

Jabłonna

-

Majątek, June 202

1.