23

8. Operation & Bandsawing Practice

- cont.

Blade Selection (TPI) - Cont.

Having selected an appropriate blade for the particular thickness and type

of material to be sawn, it is essential that the saw blade is allowed to cut

freely by not applying too much pressure.

• The need for excessive pressure is likely to be a result of the incorrect

blade selection or a worn blade and will result in inaccurate cutting and

possibly blade breakage.

Blade Selection (Width)

• When cutting shapes, the width of the blade limits the minimum radius

that can be cut.

• If the blade is too wide for the cutting radius the blade will twist and

possibly jam or break.

• The smaller the radius the narrower the blade has to be.

The diagram below provides guidance on the minimum radius to be cut

with the most commonly used blade widths.

Blade width: 3/8”

Min radius: 2

1

/

2

”

Blade width: 1/4”

Min radius: 1

1

/

16

”

Blade width: 1/2”

Min radius: 3

1

/

4

”

Material

Material Thickness

<6mm

6-12 mm 12-25 mm >25 mm

Perspex

16 TPI

14 TPI

-

-

Chipboard

-

6 TPI

3-6 TPI

3-4 TPI

Fibre board

16 TPI

14 TPI

-

-

Hardboard

10 TPI

-

-

-

Plywood

10 TPI

8 TPI

6 TPI

3-4 TPI

Strawboard

14 TPI

10 TPI

-

-

Cork

14 TPI

6 TPI

3 TPI

3-4 TPI

Leather

14 TPI

-

-

-

Rubber

10 TPI

8 TPI

-

-

Wood -log

-

-

-

3-4 TPI

Wood -soft

6 TPI

3-6 TPI

3-4 TPI

3-4 TPI

Wood -hard

6 TPI

3-6 TPI

3-4 TPI

3-4 TPI

Wood -wet

-

-

-

3-4 TPI

Summary of Contents for BS300E Premium

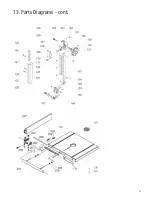

Page 33: ...33 13 Parts Diagrams cont ...

Page 34: ...34 13 Parts Diagrams cont ...

Page 35: ...35 13 Parts Diagrams cont ...