21

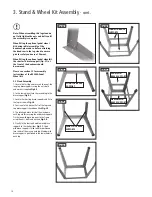

Fig.7.2

Fig.7.3

7. Drive Belt Adjustment & Speed Change

7.1 Adjusting the drive belt tension

Use the belt tensioning handle

(See Fig.7.1)

to adjust the tension of the

drive belt. Rotate the handle anti-clockwise to increase the tension and

clockwise to decrease tension. As a guide the belt is adequately tensioned

when using the index finger to impart reasonable pressure on the belt -

the belt should not deflect more than 1/4”. But like tensioning a bandsaw

blade, this is very subjective and the best test is in operation, if the belt

isn’t slipping or wearing excessively and there is adequate power being

applied to the band wheels then the drive belt is tensioned correctly.

After any adjustment of the belt ensure the poly vees are

correctly located in the vee slots as failure to do so could

damage the belt in use.

7.2 Changing the Blade Speed

The BS300E has two blade speeds 820 m/min for wood and 380 m/min for

some plastics and acrylics. This machine is not suitable for cutting metals.

The lower band wheel has two integral multi vee form pulleys and the

motor shaft has a twin multi vee form pulley.

The vee belt passes around the band wheel pulley, the motor pulley and

the plain tension roller. The belt tension is released and applied by using

the crank handle, this moves the tension roller and allows the speed to be

changed

(See Fig.7.1)

.

High Speed 820 m/min

Before changing the speed always make sure the machine has been

isolated from the mains supply. For the high speed the belt should be fitted

to the rear pulley on both the motor and band wheel.

(See Fig.7.2).

Lower Speed 380 m/min

Before changing the speed always make sure the machine has been

isolated from the mains supply. For the low speed the belt should be fitted

to the front pulley on both the motor and band wheel

(See Fig.7.3).

CAUTION!

Before carrying out any adjustments or maintenance ensure

that the machine is isolated and disconnected from the

electricity supply.

Fig.7.1

i

Kg

i

Kg

i

Kg

BELT TENSIONING HANDLE

Summary of Contents for BS300E Premium

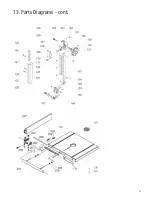

Page 33: ...33 13 Parts Diagrams cont ...

Page 34: ...34 13 Parts Diagrams cont ...

Page 35: ...35 13 Parts Diagrams cont ...