14

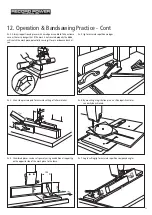

8. Machine Assembly - Cont.

90º

90º

Fence Alignment 1

Adjustment can be made to the fence (Fig. 8.6, A) in

relation to being parallel to the blade. This is done by

slackening the four wing nuts on the fence rail (Fig. 8.6, B)

and adjusting the rails position until the fence is parallel

to the blade.

Note:

This adjustment must be made with the fence in a

clamped position

Fig. 8.6

A

B

Fence Alignment 2

Check that the fence (Fig. 8.7, A) is 90º to the table

(Fig. 8.7, B) using a suitable square, there is no need for

adjustment as this area is factory set. However if settings

have slipped during transit slight adjustment may be

needed. The best way to adjust this is by adding extra

washers or shims between the fence rail (Fig. 8.7, D) and

the underside of the table where required.

Tip:

When an accurate cut is crucial it is good practice to

check all settings before machining the workpiece

and make a test cut with some scrap material.

Fig. 8.7

A

B

D

C

i

Kg

i

Kg

Fitting the Rip Fence

1. Slide the rip fence (Fig. 8.5, A) assembly onto the fence

rail (Fig. 8.5, B) ensuring that the retaining plate at the

end of the rip fence is located under the rear edge of

the table.

2. Pull down the locking lever (Fig. 8.5, C) to secure

the position.

Checking the Drive Belt Tension

The tension of the drive belt must also be checked before

operation of the machine. Please see the maintenance

section of the manual for further details.

Tip:

When locking the rip fence it is advisable to place

downward pressure on the top of the fence with one

hand. This ensures that the fence registers correctly in

the fence rail.

i

Kg

Fig. 8.5

A

B

C

Summary of Contents for BS10

Page 32: ...32 15 Parts list and Diagrams Cont ...

Page 33: ...33 15 Parts list and Diagrams Cont ...

Page 35: ...35 ...