82

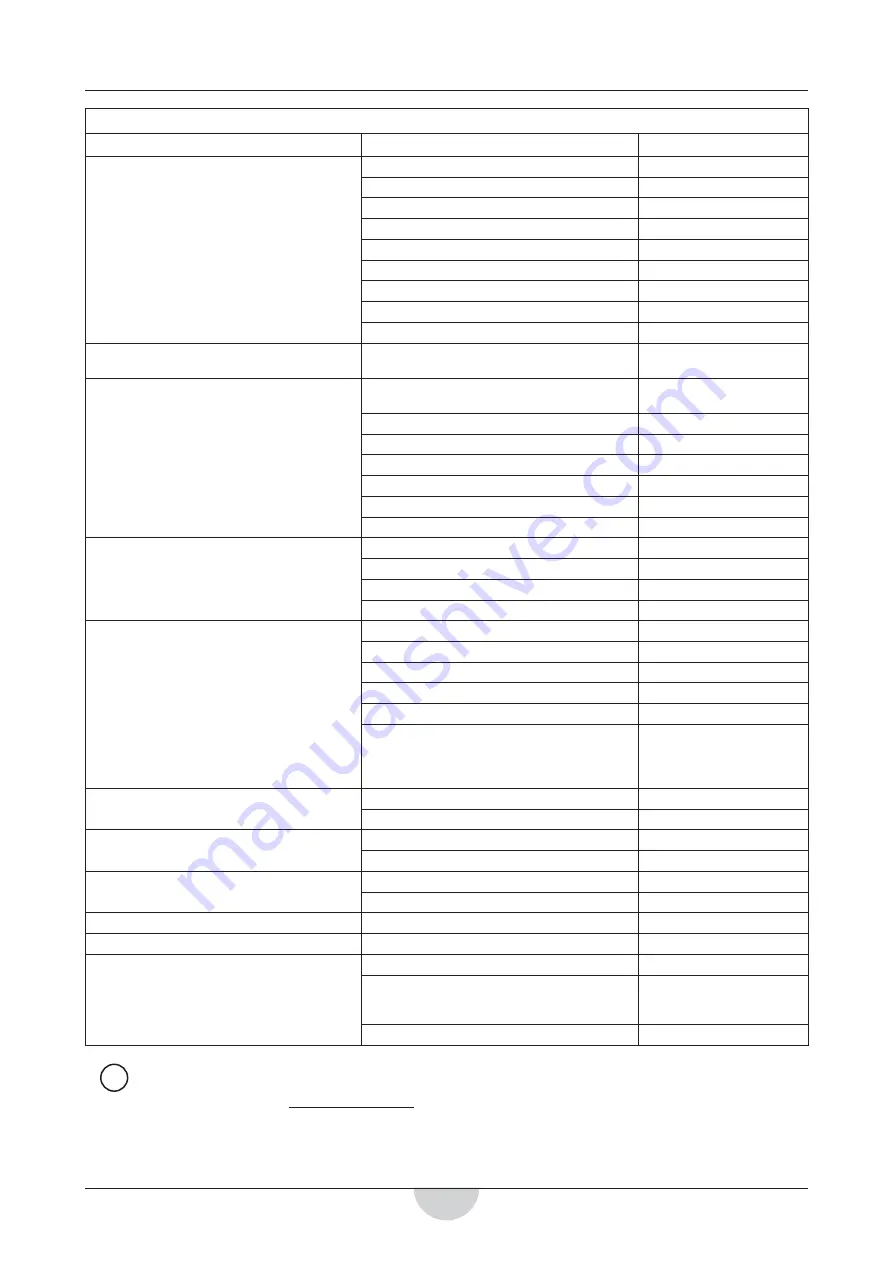

TROUBLESHOOTING

FAULT

CAUSE

REMEDY

Squeegee does not dry perfectly.

Squeegee rubbers worn.

Replace.

Squeegee fouled.

Clean.

A foreign body has become jammed in the squeegee.

Remove body.

Vacuum pipe removed or fouled.

Restore or clean pipe.

Filter 12 and cup 13 fouled.

Clean

Squeegee not properly adjusted.

Adjust.

Water drain tap open.

Close it

Vacuum motor burnt.

Replace.

Vacuum motor carbon brushes worn.

Replace.

The detergent solution is not

fl

owing out evenly onto the

brushes.

Pipelines which supply water to the brushes are fouled. Clean pipelines.

The detergent solution does not reach the brushes or

only a little is reaching them.

Pipelines which supply water to the brushes are fouled. Clean pipelines.

Solution tap does not opening.

Check tap.

Feeding pipe squashed.

Restore pipe or replace.

Tank without water.

Fill tank with water.

Solution

fi

lter fouled.

Clean it.

Electrovalve fault.

Replace it.

Pump (optional) fault

Repair it or replace.

The machine does not clean properly.

Brushes much worn.

Replace.

Detergent not suitable.

Change the detergent.

Brushes unsuitable for type of

fl

oor.

Use a suitable type of brush.

Working speed too high.

slow down.

The machine does not start.

Main key switch 1

fi

g.1 has not inserted.

Insert and turn the key on pos.1.

The batteries are

fl

at.

Check batteries or recharge.

Batteries disconnected.

Connect batteries.

Fuse (F4 - Fig.10) for dashboard, blown.

Read NOTE: ( ! )

Fuses blown (

fi

g.10).

Read NOTE: ( ! )

Emergency stop button engaged.

Release the button and repe-

at the start-up procedure (see

USING THE SCRUBBER/

DRIER. -

fi

g.3)

The machine does not start or it stops suddenly.

Led on the dahsboard lights on

see “DIAGNOSTIC -LED 3 - pag.62”.

Batteries disconnected.

Connect batteries.

The machine does not travel forward or reverse.

Forward or Backward switch closed at power-on

.

see “DIAGNOSTIC -LED 3 - pag.62”.

Drive gear motor damaged or carbon brushes worn.

Replace motor or its carbon brushes.

The vacuum motor switches off or does not start.

Vacuum motor damaged or carbon brushes worn.

Replace motor or its carbon brushes.

Fuse blown (F3 - Fig.10).

Read NOTE: ( ! )

The machine has dif

fi

culty moving.

Brake engaged.

Release the brake.

Water leaks with machine stopped.

The Tap is open or vacuum pipelines is broken.

Close tap or replace pipelines.

The squeegee does not lift and does not low.

Fuse blow (F2 - Fig.10).

Read NOTE: ( ! )

The actuator does not receive current.

Check actuator

(see also DIAGNOSTIC DISPLAY

4 - pag.64).

The actuator motor damaged.

Replace.

!

NOTE:

Before replace the fuses contact the Authorized service staff.

Never use fuses of higher rating as this may cause damage. If the fuses blow repeatedly there is a fault on the machine.

Summary of Contents for 33.MG.101

Page 27: ...27 FIG 2 A 6 3 3 6 8 8 4 2 2 7 1 1 5 8 9 9 ...

Page 31: ...31 FIG 2 B 1 5 6 7 2 4 3 ...

Page 48: ...48 FIG 6 3 3 4 1 2 2 ...

Page 50: ...50 FIG 7 1 2 3 4 ...

Page 52: ...52 FIG 8 5 4 2 3 1 6 7 8 9 ...

Page 56: ...56 FIG 9 3 4 A 3 4 A 1 8 9 10 11 12 7 6 MEGA I MEGA I S special 2 2 5a 5b ...

Page 74: ...74 FIG 12 4 3 1 2 ON OFF ON OFF KIT A KIT B 7 7 6 5 8 8 MEGA I S special ...