2.3 CABLING AND POWER

SUPPLIES

2.3.1 Signal Cabling

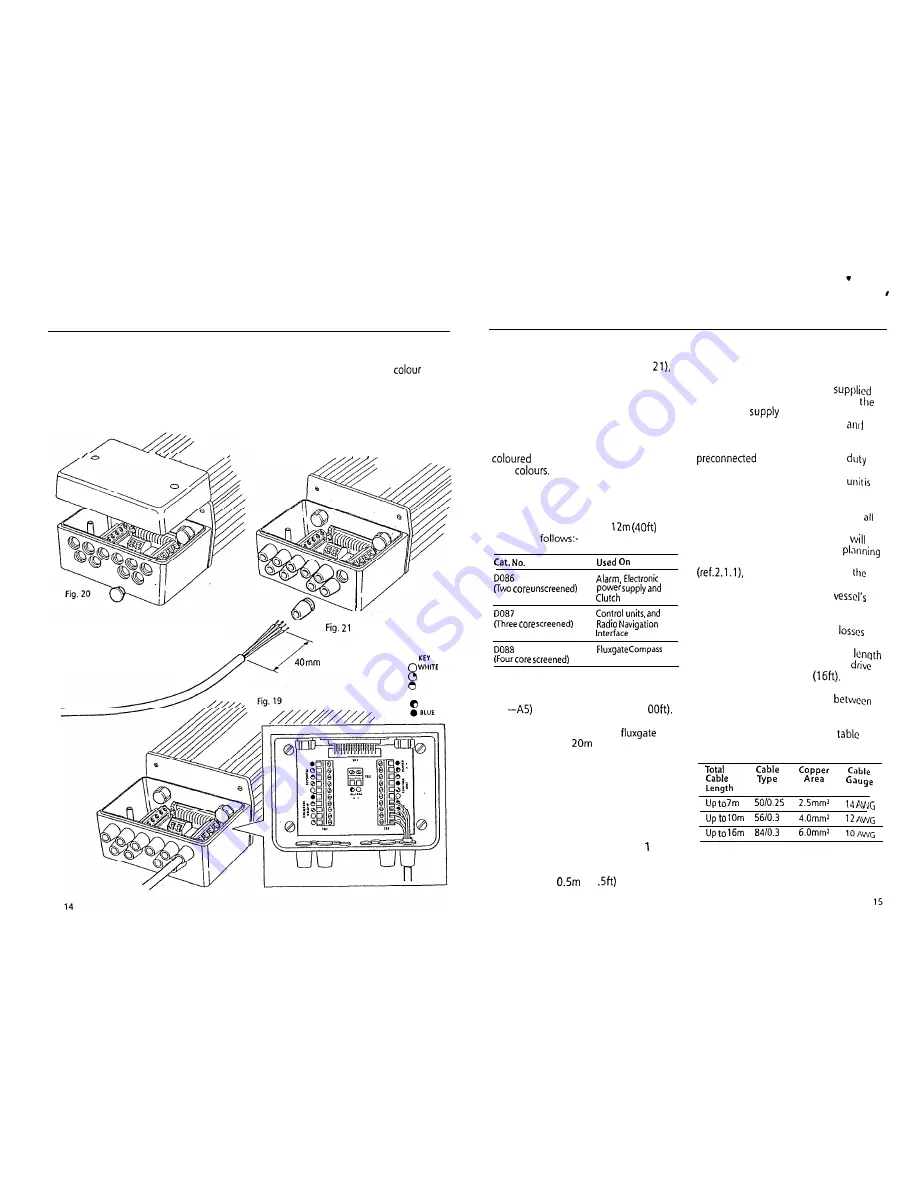

Cable interconnections between all sub

system modules are shown schematically

(in Figs 1 and 12). All peripheral units

connect to the connector unit where they

are permanently hard wired to

coded connector blocks situated on a

central printed circuit board (Fig. 19).

The end face of the connector unit is

fitted with ten blanking discs (Fig. 20).

which are easily pressed out and replaced

by the special rubber grommets supplied

with each peripheral unit fixing kit

,

YELLOW

GREEN

@ R E D

BROWN

(Fig. 2 1). After cutting the

interconnecting cable to length (Fig.

it may be passed through the inserted

rubber grommet and prepared for

connection to the relevant connector

block (Fig. 19).

Each connector block is clearly

identified on the printed circuit board and

each wire position is identified by

dots which match the individual

wire

The cable screen should be

connected to terminals identified by a

white dot.

Each peripheral unit is supplied with 6m

(20ft) of interconnecting cable. Additional

cabling can be supplied in

cut

lengths as

The total length of screened core cable

connected to the serial bus (connectors

Al

should not exceed 30m (1

Similarly, the total length of

interconnecting cable to the

should not exceed

(60ft). If it is

necessary to exceed the above maximum

length recommendations, please consult

Nautech’s Product Support Department

for specific advice. In general the length

of interconnecting cables should be kept

to an absolute minimum to reduce the

possibility of interference by other

electronic equipment.

All cables should be run at least m

(3ft) from existing cables carrying radio

frequency or pulsed signals, and should

be clamped at

(1

intervals.

2.3.2 DC Power Supplies

(Fig. 22).

Flexible connection tails fitted with

insulated spade connectors are

with the course computer to connect

main power

(Blue and Brown) and

drive unit motor connections (Red

Black).

All four flexible wire tails are

to a four-way heavy

terminal block for connection to the main

power cabling. Similarly, the drive

supplied with flexible tails for the motor

power connection (Red and Black).

Before commencing power cabling,

interconnecting terminal blocks should be

screwed into a position where they

remain dry and protected. When

the position of the course computer

it is important to reduce

overall length of heavy power cable

between the drive unit and the

central power distribution panel to a

minimum.

Excessive lengths will generate

in

the cable and will reduce system

performance. In addition, the cable

between the course computer and

unit must be less than 5m

Having sited the course computer,

measure the total cable length

the drive unit and the vessel’s central

distribution panel and select the

appropriate cable size from the

below.