RG165T-R Operator · Service · Maintenance

14

Safety

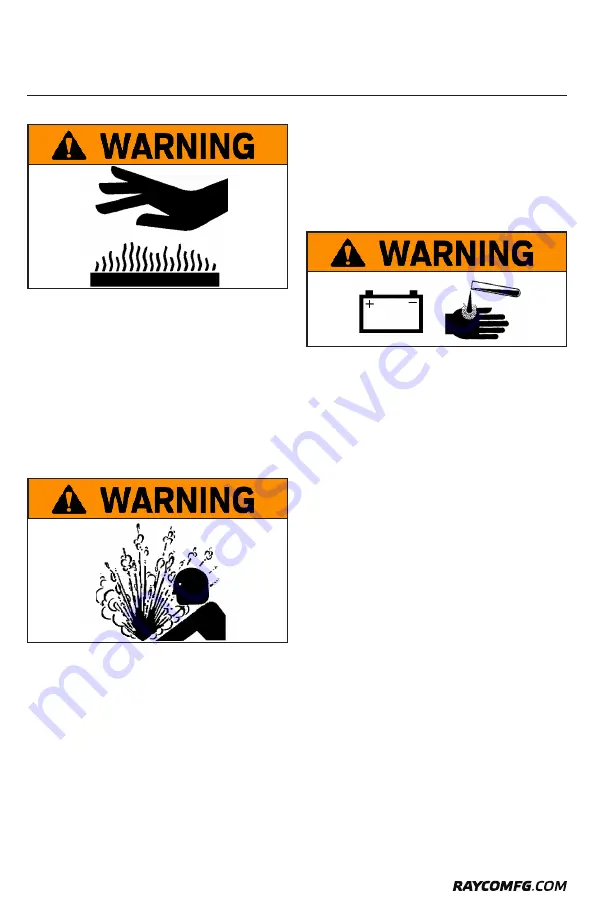

Burn Prevention

Do not touch any part of an operating engine. Allow the

engine, radiator, exhaust and hydraulic reservoir to cool before

any maintenance is performed. Relieve all pressure in the

air system, oil system, lubrication system, fuel system, and/

or in the cooling system before any lines, fittings or related

items are disconnected.

In addition, avoid contact with other related hot engine parts

such as exhaust manifolds, turbochargers and mufflers.

External exhaust parts become very hot during operation.

Paper, cloth, and wooden materials could ignite if they come

in contact with these parts.

Coolant

When the engine is at operating temperature, the engine

coolant is hot. The coolant is also under pressure. The

radiator and all lines to the heaters or to the engine contain

hot coolant.

Any contact with hot coolant or with steam can cause severe

burns. Allow cooling system components to cool before the

cooling system is drained.

Check the coolant level only after the engine has been stopped.

Ensure that the filler cap is cool before removing the filler

cap. The filler cap must be cool enough to touch with a bare

hand. Remove the filler cap slowly in order to relieve pressure.

Cooling system conditioner contains alkali. Alkali can cause

personal injury. Do not allow alkali to contact the skin, the

eyes or the mouth.

Oils

Hot oil and hot components can cause personal injury. Do

not allow hot oil to contact the skin. Also, do not allow hot

components to contact the skin.

Remove the hydraulic tank filler cap only after the engine

has been stopped. The filler cap must be cool enough to

touch with a bare hand. Follow the standard procedure in

this manual in order to remove the hydraulic tank filler cap.

Batteries

Electrolyte is an acid. Electrolyte can cause personal injury.

Do not allow electrolyte to contact the skin or the eyes.

Always wear protective glasses for servicing batteries. Wash

hands after touching the batteries and connectors. Use of

gloves is recommended.

Fire & Explosion Prevention

All fuels, most lubricants, and some coolant mixtures are

flammable.

Flammable fluids that are leaking or spilled onto hot surfaces

or onto electrical components can cause a fire. Fire may

cause personal injury and property damage.

Remove all flammable materials such as fuel, oil, and debris

from the machine. Do not allow any flammable materials

to accumulate on the machine. Serious personal injury can

occur when fuel or oil is spilled on yourself or your clothes,

which can ignite.

Store fuels and lubricants in properly marked containers away

from unauthorized persons. Store oily rags and any flammable

materials in protective containers. Do not smoke in areas

that are used for storing flammable materials.

Do not operate the machine near any flame.

Extinguish all cigarettes, cigars, pipes and other sources

of ignition.

Exhaust shields (if equipped) protect hot exhaust components

from oil spray or fuel spray in case of a break in a line, in a

hose, or in a seal. Exhaust shields must be installed correctly.

Do not weld on lines or on tanks that contain flammable fluids.

Do not flame cut lines or tanks that contain flammable fluid.

Clean any such lines or tanks thoroughly with a nonflammable

solvent prior to welding or flame cutting.

Check all electrical wires daily. Repair any wires that are

loose or frayed before you operate the machine. Clean all

electrical connections and tighten all electrical connections.

Dust that is generated from repairing nonmetallic hoods or

non metallic fenders can be flammable and/or explosive.

Repair such components in a well ventilated area away from

open flames or sparks.

Summary of Contents for RG165T-R

Page 23: ...RG165T R Operator Service Maintenance 800 392 2686 23 Safety ...

Page 24: ...RG165T R Operator Service Maintenance 24 Operation 11 7 1 3 2 5 6 8 4 9 10 12 13 14 15 16 ...

Page 47: ...RG165T R Operator Service Maintenance 800 392 2686 47 Maintenance ...

Page 62: ...RG165T R Operator Service Maintenance 62 Hydraulic Schematic 806797 TOP ...

Page 63: ...RG165T R Operator Service Maintenance 800 392 2686 63 Hydraulic Schematic 806797 TOP BOTTOM ...

Page 69: ...RG165T R Operator Service Maintenance 800 392 2686 69 ...