6

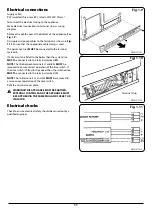

Controls

Independent temperature controls with time switch control

are recommended for providing temperature comfort from

radiators.

Typical controls can be motorised valves operated by room

thermostat and cylinder thermostat.

Thermostatic radiator valves may be fitted if required

and consideration should be given to fitting a frost

thermostat which should set to operate at a temperature of

approximately 4ºC.

The boiler should be controlled so that it operates on

demand only.

Operation of the system under control of the boiler

thermostat only, does not produce the best efficiency.

Refer to the control equipment manufacturer’s literature for

information e.g wiring.

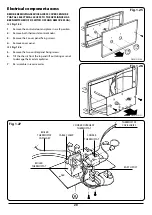

The internal boiler/cooker wiring diagram is shown in

Fig.

1.12on page 12

.

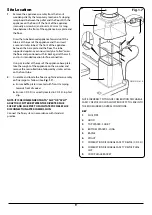

Flue system

Open Flue

The following notes are intended to give general guidance.

The cross sectional area of the flue serving the cooker must

not be less than the area of the flue outlet of the cooker

(12,273mm2). If flue pipe is to be used it must not be less than

125mm internal diameter.

A straight vertical section of the flue pipe of a length not

less than 600mm must be utilised immediately above the

draught diverter before any bends are used. Bends not

less than 135º must not be used. The equivalent height of

the flue must be a minimum of 3m in length.

Flue pipes and fittings should be constructed from one of the

following materials:-

a.

Cement

b.

Aluminium or stainless steel

c.

Cast iron or mild steel acid resistant vitreous enamel

lined.

If a chimney is to be used, it should be one that is composed,

of or lined with, a non-porous acid resistant material.

A flue pipe constructed in (a) to (c) above, should form the

initial connection to lined chimneys.

Where a chimney is to be used, which is not composed of or

lined with a non-porous acid resistant material, it should be

lined with a stainless steel flexible flue liner, in accordance

with relevant standards.

Before connecting the appliance to or inserting a liner

into a flue that has been previously used, the flue must be

thoroughly swept clean of any soot and loose materials. If a

baffle plate, etc is fitted in the flue it must be removed before

connecting the appliance to, or inserting a liner into the flue.

The flue should terminate in accordance with relevant

recommendations.

Flue Terminal

The total free area of the openings in the flue terminal must

be a minimum of 24,546mm2 = (cross sectional area of

125mm dia flue x 2) in the UK GC1 and GC2 terminals meet

this requirement.

Air requirements

The following notes are intended to give general guidance:-

Kitchen or Internal Space Air Supply

Wherever an open flue appliance is to be installed it must

have a permanent air vent. This vent must be either direct to

outside air or to an adjacent room or internal space which

itself must have a permanent air vent of at least the same size

direct to outside air.

The minimum effective area of the permanent air vent in the

outside wall must be 147cm2.

Effect of an Extract Fan

It may be necessary to increase air vent by 50% or consult fan

manufacturers. If there is any type of extract fan fitted in the

same room as an open flue appliance there is a possibility

that if adequate air inlet are from outside is not provided,

spillage of the products from the appliance flue could occur

when the extract fan is in operation. Where such installations

occur, a spillage test must be carried out and any necessary

remedial action taken.