43

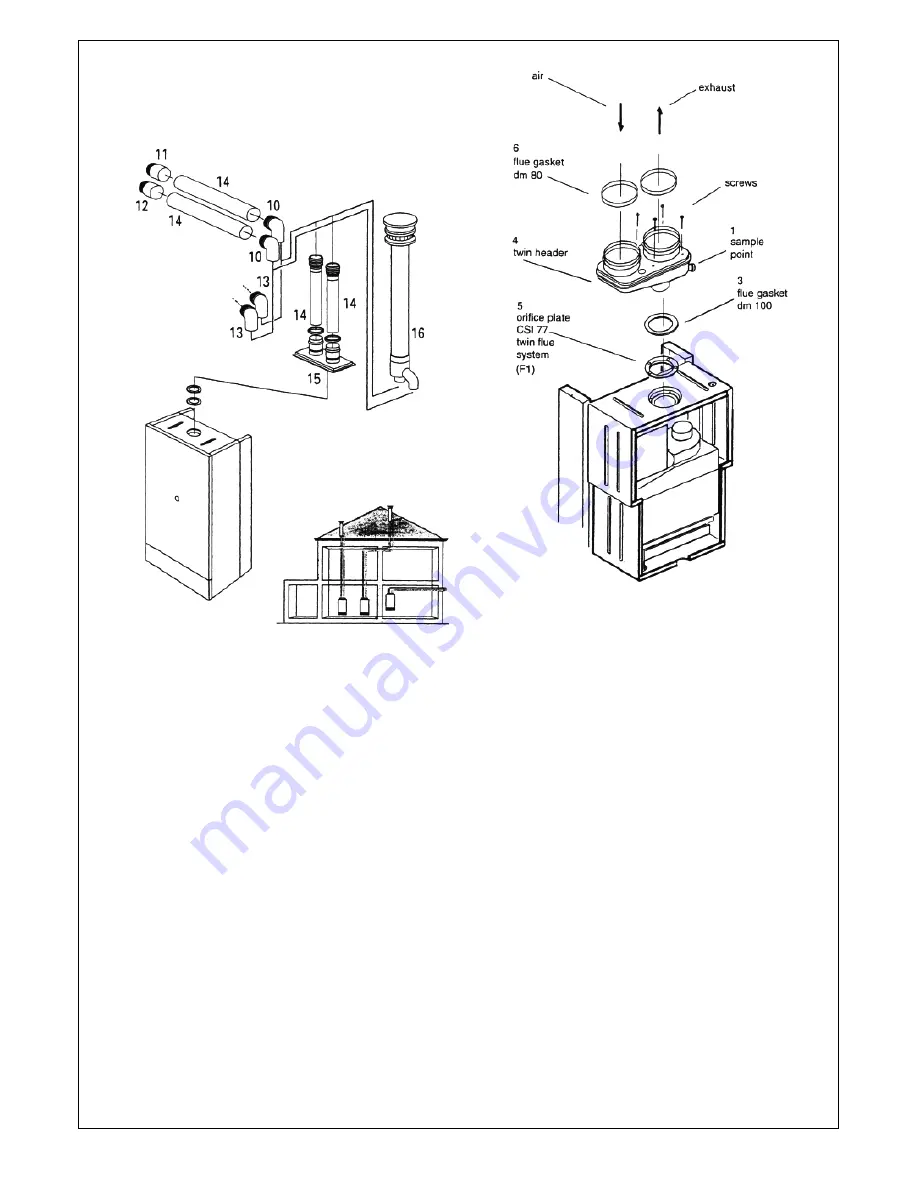

SECTION 10 INSTALLATION INSTRUCTION FOR

TWIN FLUE PIPE (ECCENTRIC FLUE DUCT SYSTEM).

10 - air intake bend 90°

10 - fl ue exhaust bend 90°

11 - air inlet terminal

12 - fl ue exhaust terminal

13- 45° air intake bend duct

13 - 45° fl ue exhaust bend

14 - fl ue exhaust duct

14 - air intake duct

15 - two-way fl ue gas header

16 - vertical eccentric fl ue exhaust duct

10.1 IMPORTANT.

These instructions must be read in

conjunction with the installation and

servicing

instructions.

As with all fl ues the kits must be installed

taking due account of the current issue of BS

5440 parts 1 & 2 and timber frame housing

REF

DM2.

Also note that the requirements will vary

depending upon the kit being installed.

Guidance is provided but unless otherwise

stated, always comply with the

recommendations of the relevant codes of

practice.

10.2

TWIN FLUE INSTRUCTIONS.

This part of the installation manual covers the

installation

and

fi xing instructions of the twin

fl ue eccentric fl ue duct systems only.

When ordering twin fl ue it must be stated for

CSI SYSTEM 780 series range.

Typical installation procedures are illustrated

by

drawings.

IMPORTANT

Correct F1 orifi ce must be fi tted.

Supplied with the CSI twin fl ue header is a

F1 orifi ce plate along with supplementary

depression seal.

Before fi xing the twin fl ue system the existing

orifi ce plate must be replaced with F1 also

ensuring supplementary seal has been fi tted.

Remove the 13 screws securing the

depression front panel item 2 fi gure 39 to

expose front edge of depression chamber

(Twin fl ue instructions fi gure 1 adjacent) Using

adhesive sponge supplied with CSI twin fl ue

header, carefully attach to depression

chamber so as to create a softer seal.

Taking care not to damage the new seal,

carefully re-fi t the depression chamber front

cover in reverse order.

Take out the 4 temporarily fi tted securing

screws, lifting out the gasket and orifi ce plate

disconnecting it from the venturi tube.

Discard this orifi ce plate and re-fi t the F1 ori-

fi ce plate ensuring that the venturi tube has

been re-fi tted, making sure this is securely

located into the locating peg.

Fig. 60

Fig. 61

Summary of Contents for 780 Series

Page 2: ......

Page 7: ...7 Fig 3 OVERALL DIMENSION ...

Page 34: ...34 Fig 45 Fig 44 Fig 46 ...

Page 36: ...36 Fig 48 Fig 47 Fig 49 Fig 50 Fig 51 ...

Page 42: ...Fig 59 42 SECTION 9 ELECTRICAL SYSTEM DIAGRAM ...

Page 46: ...79 83 105 46 50 27 16 39 17 2 22 100 1 4 5 11 8 SECTION 11 ...

Page 49: ...49 ...

Page 50: ...COD 0017LIB06010 2 03 2010 ...