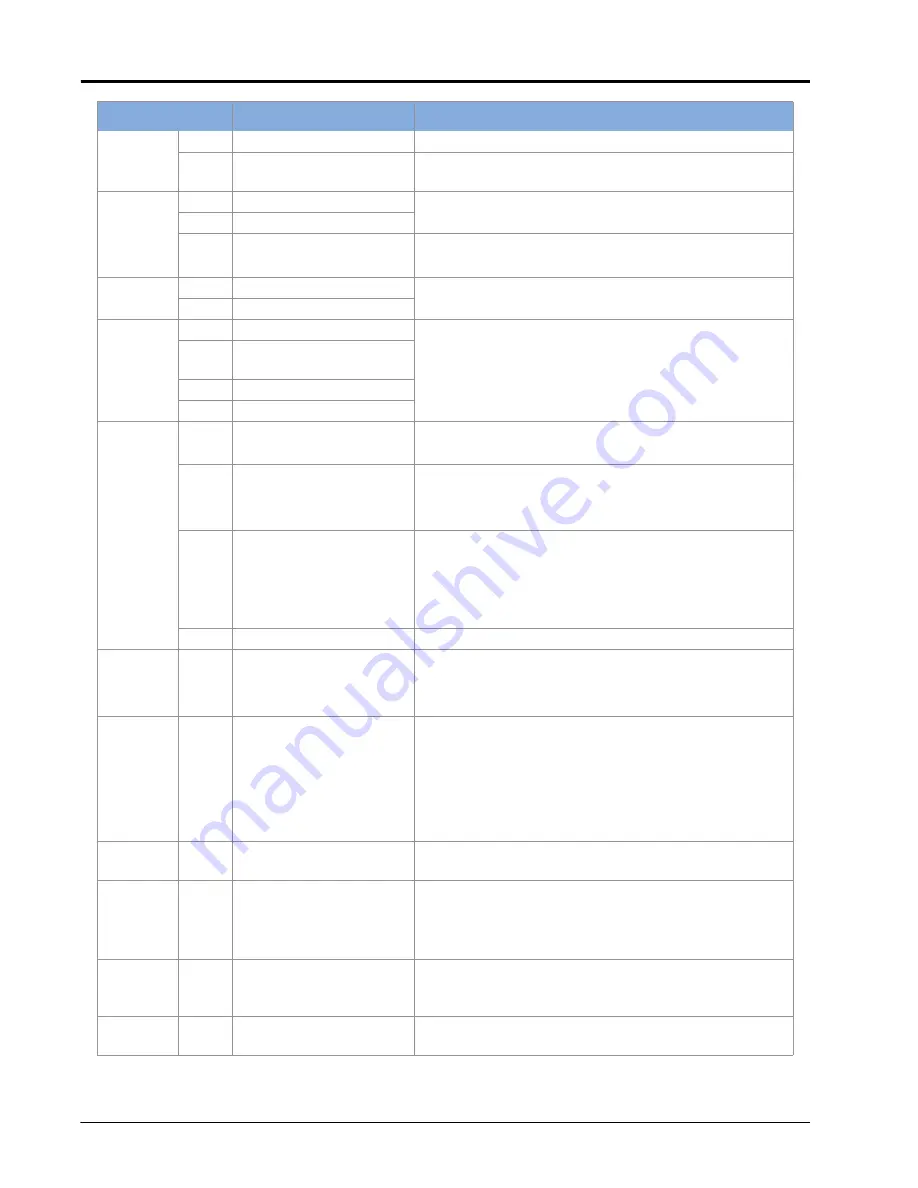

CHAPTER 9

72

Raven SC1™/TC1™ Calibration & Operation Manual for Towed Implements

516119

.2

Lockout switch invalid.

Check cabling and connections.

.31

Lockout switch pressed.

Toggle the lockout switch off. If DTC does not clear, check

lockout switch cabling.

522240

.16

GGA rate high.

Cycle power to the machine.

.18

GGA rate low.

.31

No GPS comm

1. Leave SC1/TC1 powered on for 10 minutes.

2. Cycle power to the machine.

522242

.16

ZDA rate high.

Cycle power to the machine.

.18

ZDA rate low.

522250

.0

End of line error.

Contact Raven technical service.

.15

Maximum point space

error.

.16

Segment angle error.

.17

Minimum point space error.

522250

.2

Curvature invalid.

1. Reset or update the field computer.

2. Contact a local Raven dealer for additional assistance.

.31

No guidance path.

1. Cycle power to the Raven field computer.

2. Ensure the Raven field computer is used for guidance.

3. Start a job and create an A-B guidance line.

.7

Maximum cross-track error

(XTE) exceeded.

1. Recalibrate the SC1/TC1 steering system, including the

hydraulic calibration.

2. Check hydraulic steering performance. Refer to the

Wheel Control Settings

section on page 41 for

additional assistance.

.8

Lookahead too large.

Contact Raven technical service.

522260

.31

No guidance partner.

Field computer is not registered as a guidance partner.

1. Cycle power to the Raven field computer.

2. Update the field computer software.

522261

.31

No steering control unit

(SCU) detected.

1. Check cabling and connections to the steering valve.

2. Cycle power to the machine.

3. Update the steering valve software.

4. Check for CAN communication errors between the

steering valve and the SC1/TC1. Check CAN terminators

and wiring.

522268

.31

No field computer.

Check cabling and connections between the field

computer and the SC1/TC1.

522390

.9

Engage switch error.

1. Check the resume switch status in the universal

terminal. Ensure the status changes when the engage

switch is pressed.

2. Check cabling and connections to the resume switch.

522810

.14

Vision mode invalid

partner.

VSN not supported by MDU steering. Switch to GPS

guidance or contact your local Raven dealer for assistance

with upgrading to HDU steering.

522811

.14

Roadway homologation

terms.

Homologation terms not accepted by the operator.

Accept the terms of the Roadway Homologation.

Code ID

Description

Recommended Actions