Brochure for models with FLASH motherboard

( fi rmware version ECT2008air - & ECT2008box - )

PAGE

C - Work phase

DispLaY shOWing “WORK”: the stove carries out all the powers from pR 01 until it reaches the set one, while the heat exchanger, if

the pR 15 “eXChangeR thReshOLD” is satisfi ed, switches on immediately at the set power.

When the stove is fi nally in work phase (ie. it reaches the preset power) the exhaust blower and the auger will follow the param-

eters corresponding to the requested work power (from pR 18 to pR 22 for the exhaust blower, from pR 6 to pR10 for the auger

and from pR 23 to pR 27 for the room blower).

each time the running power is changed it will take 40 seconds before a complete change is made.

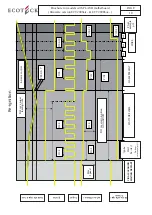

DeCRease in pOWeR

inCRease in pOWeR

from p5 to p4

40’’

from p1 to p2

40’’

from p4 to p3

40’’

from p2 to p3

40’’

from p3 to p2

40’’

from p3 to p4

40’’

from p2 to p1

40’’

from p4 to p5

40’’

if, during the work phase, the smoke temperature reaches the maximum threshold (pR 14) the stove goes into ventilation to reduce the tempera-

ture. if the ventilation is not suffi cient and the temperature continues to increase, reaching 269 ° C/ 516 F the stove automatically goes into „sMOKe

OVeR teMpeRatURe aLaRM“.

if the switchboard indicates a constant decrease in temperature due to extinction of the fl ame, the stove goes to ”nO peLLet aLaRM” reaching

the threshold set in the parameter pR 12 (“nO peLLet thReshOLD“) .

iMpORtant!!! even if the smoke temp. reaches the value set in the pR 15, the heat exchanger does not switch on until the

stove goes to WORK mode; this condition is necessary in order to avoid “jumps” in the tsmoke in FLaMe pResent, with the risk

of displaying an unusual FLaMe anOMaLY aLaRM.

the DispLaY shOWs “FiRe pOt CLeaning”: in this phase the stove cleans the fi re pot according to the interval between cleaning

operations of pR 03. the duration of each cleaning operation is regulated by the parameter pR 04. the exhaust blower turns

according to the pR 29 settings with a pellet load of pR 30.

the purpose of this function is to prevent the fi repot from clogging when the stove remains in operation for many hours during

the day.

D - Modulation phase

DispLaY shOWing “MODULatiOn WORK”: the temperature set by the ambient thermostat is reached, irrespective of the work

power in which it fi nds itself. the stove goes on to work power 1 and will stay on power 1 until there is a drop in the room

temperature.

e - Comfort Climate

activate or Deactivate by holding buttons 4 & 6 together.

the Comfort Climate will shut the stove down when your desired room

temperature is reached, then it will turn the stove back on when the room

temperature drops below the diff erncial set.

eXaMpLe: in this case, the desired room temperature is 70°F and the

Comfort Climate diff erencial is 2°F. the stove will shut down at 70°F and restart at 68°F.

FUnCtiOning: the value sets the temperature the stove goes back on again.

6

2°

pr 42

COMFORt

CLiMate