RAPPORTO DI INSTALLAZIONE

INSTALLATION REPORT- INSTALLATIONSBERICHT

DA COMPILARE A CURA DELL’INSTALLATORE

TO BE COMPLETED BY THE FITTER - DURCH DEN MONTEUR AUSZUFÜLLEN

Sollevatore modello

Lift model

Hebebühne Modell

Operazione di controllo

Control operation - Kontrolloperation

•

Verifica della tensione di alimentazione

_____________________________________________________________

Power voltage check

Kontrolle Stand Tragmutterverschleiss

• Interruttore generale

____________________________________________________________________________

Main switch

Hauptschalter

• Comando salita e discesa

________________________________________________________________________

Up/down control

Steuerung Heben und Senken

• Corretto senso di rotazione del motore

______________________________________________________________

Correct direction of motor rotation

Richtige Drehrichtung des Motors

• Controllo funzionamento valvola taratura centralina e piombatura

________________________________________

Control unit setting valve operation and seal inspection

Kontrolle Funktionstüchtigkeit Eichventil Schaltschrank und Lotung

• Controllo funzionamento valvola discesa

___________________________________________________________

Downward movement valve inspection

Kontrolle Funktionstüchtigkeit Absenkventil

• Controllo coppia di serraggio delle viti di fi ssaggio colonna al pavimento

___________________________________c

Tightening torque control of retention screws securing column to floor

Kontrolle Anziehmoment der Arretierschrauben Säule an Fussboden

• Controllo corretto scorrimento dei bracci telescopici

__________________________________________________c

Telescopic arms correct sliding control

Kontrolle einwandfreies Gleiten der Teleskoparme

• Controllo corretto inserimento e sgancio degli arresto bracci

____________________________________________c

Correct arm stop engagement and release control

Kontrolle einwandfreies Ein- und Ausklinken der Armarretierungen

• Controllo livello olio centralina

_____________________________________________________________________c

Screw lubrication device level control

Kontrolle Schaltschrank-Ölstand

• Controllo lubrificazione delle guide di scorrimento

____________________________________________________c

Slide guide lubrication control

Kontrolle Schmierung der Gleitführungen

• Controllo della esatta collocazione dei dispositivi salvapiedi

_____________________________________________c

Foot guard devices exact position control

Kontrolle genaue Anordnung der Fussabweiser

• Controllo della presenza e collocazione degli adesivi ___________________________________________________

c

Adhesive and adhesive position check

Kontrolle Vorhandensein und Anbringung der Kleber

• Portata

- Carrying capacity

-

Tragfähigkeit ____________________________________________________________

c

• Avvertenze

- Warnings

-

Hinweise __________________________________________________________________

c

• Matricola

- Serial number

-

Serie-Nr. ________________________________________________________________

c

Firma e timbro dell’installatore

Data di installazione

Fitter’s signature and stamp - Unterschrift und Stempel des Monteurs

Installation date - Datum der Installation

matr.

serial number

Serie-Nr.

Summary of Contents for KPH370.70 LIKT

Page 7: ...7 0 0488 M001 2...

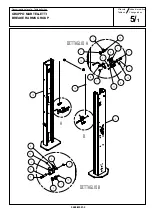

Page 29: ...29 6 3e 3c 3a 3b 3d 3g 1 20 25mm 3f 3f A B C STOP A A B B C C 0488 M001 2...

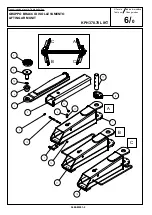

Page 33: ...33 6 Fune Rope 5b 5c n 2 viti Screw 5d Flex Hose 5a 260 660 700 525 260 165 75 0488 M001 2...

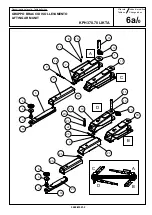

Page 34: ...34 6 F F1 7 5 X 360mm 3 5 X 140 mm 8b 8a 8c 8d 8e 8e 0488 M001 2...

Page 36: ...36 9a MIN MAX C 9a OK STOP 9b Fune Rope 6 0488 M001 2...

Page 38: ...38 6 F1 F1 10a 10b 3 5 X 140 mm F1 F1 F1 F1 F1 F1 F1 F1 0488 M001 2...

Page 39: ...39 11a 11b 11c 6 0488 M001 2...

Page 42: ...42 6 0488 M001 2...

Page 44: ...44 6 MIN MAX 0488 M001 2...

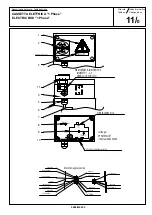

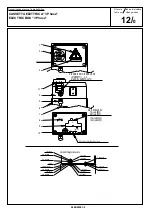

Page 48: ...48 7 ATTENZIONE WARNING ACHTUNG ATTENTION CUIDADO 1Ph 3Ph 1 1A 3 2 2 3 4 0488 M001 2...

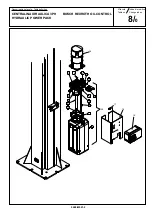

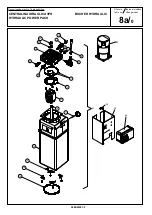

Page 52: ...52 8 0488 M001 2...

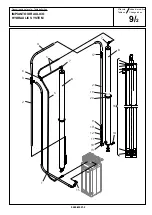

Page 54: ...54 8 360 NO A A A 0488 M001 2...