21

14. Push the Vertical Shaft down and position the Mount/

Demount Head into contact with the rim edge. (See Fig.

11.11 - 11.12)

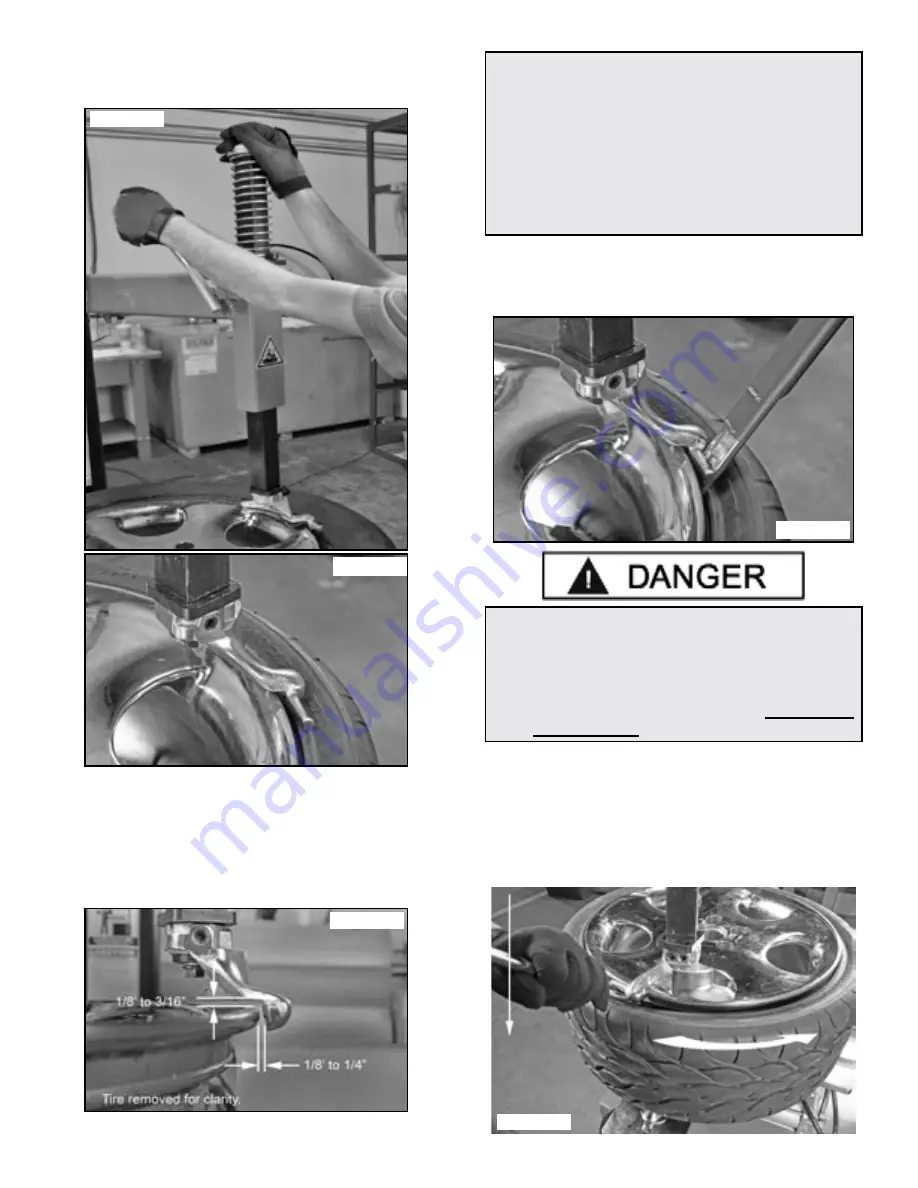

15. Push up on the locking handle to lock the Vertical

Shaft into position. As the slide is locked, the Mount/

Demount Head will move upward approximately 1/8 inch

and backward 1/8 inch from the rim edge. The Mount/

Demount head roller should not be in contact with the rim

edge. (See Fig. 11.13)

16. Insert the smooth curved end of the Bead Lifting Bead

Lifting Tool over the “duckbill” side of the Mount/Demount

Head and below the top bead of the tire.

(Fig. 11.14)

NOTE:

For Low Profile Tires, perform Step 17 to get the

upper bead into the drop center of the wheel.

17. Push the Bead Lifting Tool down away from the wheel

to lower the bead into the Drop Center while lifting up on

the Table Top Pedal to rotate the turnable counter

clockwise. (See Fig. 11.15)

NOTE:

This clearance will be maintained as long as the

Vertical Shaft remains locked. The operator may swing

the arm out of the way and back into place again

without needing to reposition the head when changing

a like set of wheels. The tool clearance may change

with machine use and should be inspected often.

Failure to maintain proper clearance may result in

damage to the wheel rim or tire. See page 34 for

adjustment procedure.

DANGER!

The Bead Lifting Tool and demount head may

encounter resistance or come under load at times

during the mount and demount procedures. Keep

one hand firmly on the tool to avoid possible tool

kick back. Use the reversing feature (lift table top

pedal upwards) to back out of jam ups.

Fig. 11.11

Fig. 11.12

Fig. 11.13

Fig. 11.14

Fig. 11.15

Summary of Contents for R980X

Page 39: ...39 ...

Page 48: ...48 ...

Page 49: ...49 RECORD ALL MAINTENANCE NOTES AND SERVICE HISTORY HERE ...

Page 50: ...50 TIRE AND WHEEL DATA ...