8

Installation Instructions

1. Safety Precautions

• To prevent an accident and/or injury, do not hoist the unit over

your shoulder. Use a hand truck to transport the unit.

• Do not lay the unit on its side.

• Wear safety glasses and work gloves during installation.

2. Test the Raw Water

• If water contains iron, manganese or hydrogen sulfide, a seperate

iron removal system is suggested to be installed prior to the

conditioner. Please consult with your local dealer.

3. Check the Water Pressure

• Use a pressure gauge to confirm that the water pressure does not

exceed 100 psi. If the water pressure does exceed this limit, install

a pressure regulator on the inlet pipe of the unit. The minimum

water pressure for a conditioner is 20 psi. 60 psi is the optimum

operating pressure.

4. Locate a Site for the System

• There are three primary requirements needed for a site: the main

water source, an air-gap drain and a grounded electrical connec-

tion. Locate the system as close to these items as practical. Drain

lines over 50 feet long, may need to be increased in size to allow the

proper flow.

• Place the system in the desired location. The location should have

a level, smooth, and clean surface.

• If the system is located outdoors, protect the unit from direct sun-

light. Direct sunlight can damage the fiberglass and other system

components. If necessary, build a box or shed.

5. Install the Valve Head

• Remove the cap plug from the tank.

• Lubricate the riser pipe O-ring and tank O-ring with Dow 111

silicone-based lubricant or equivalent.

• Attach the supplied upper basket to the bottom of the control

valve; twist to lock in place. Do not use if water contains any

amount of iron.

• Align the upper basket with the riser pipe and slowly lower the

control valve onto the riser pipe, using a twisting motion.

• Align the control valve with the tank. Push down on the control

valve and continue to turn it clockwise until the valve o-ring seals

against the tank.

6. Turn Off the Water and Drain the Plumbing

• Turn off the water at the meter or the pressure tank.

• To drain the plumbing system, open all faucets in the house and

flush the toilets. The water will drain out of the lowest faucet or

outlet.

• Do not sweat pipes with water in them or while attached to the

system; steam will damage the plastic parts in the valve.

• Do not point the soldering torch directly at the mineral tank or

control valve. These composite materials will last a lifetime, but

cannot withstand the intense heat from a torch.

Helpful Tip: The drain may be a

floor drain, a sewer trap, utility

sink, vent stack, dry well, etc.,

depending on local plumbing

codes.

Important Note: The system can

only be installed outdoors in

climates that do not reach

freezing levels.

Important Note: Do not over-

tighten the valve to the tank.

Helpful Tip: This procedure will

allow air to enter the plumbing

system.

Important Note: Not Applicable

for TC-CAB and SS Models.

Important Note: Applicable for

copper plumbing installations.

Important Note: For Massachusetts

Residents Only: The Commonwealth of

Massachusetts Plumbing Code 248 CMR

shall be adhered to. A licensed plumber

shall be used for this installation.

Summary of Contents for TC 100 CV

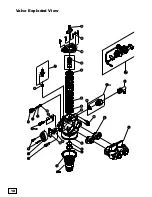

Page 18: ...18 18 Valve Exploded View ...

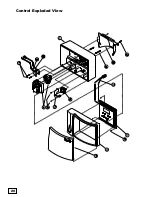

Page 20: ...20 Control Exploded View 20 ...

Page 23: ...23 Notes ...

Page 44: ...44 Vista despiezada de la válvula ...

Page 46: ...46 Vista despiezada del control ...

Page 49: ...49 Notas ...

Page 50: ...50 Notas ...

Page 51: ...51 Notas ...