4

Operational Specifications

Plumbing

3/4 inch to 1 1/4 inch I.D.

Drain Line

1/2 inch I.D.

Water Pressure

20 psi_120 psi (1.38 bar _ 6.89 bar)

Operating Temperatures

40° F_100° F (4.4° C _ 37.8° C)

Electrical Requirements

A properly grounded alternating current supply (110 VAC 60 Hz or 230

VAC 50 Hz) is required for the operation of this system. Please check the

transformer for the correct voltage requirements.

Bypass Valve

The bypass valve enables you to bypass the system in situations of: emer-

gency leaks in the equipment, service calls.

Existing Plumbing Conditions

Plumbing should be free from lime and/or iron buildup. Piping that

contains large amounts of lime and/or iron should be replaced.

Additional Specifications

• Do not install this system where water is microbiologically unsafe or of

unknown quality without adequate disinfection before or after the

system.

• This system must be installed in accordance with all applicable state

and local laws and regulations.

• The Commonwealth of Massachusetts Plumbing Code 248 CMR shall

be adhered to. A licensed plumber shall be used for this installation.

• This system must be installed in an area not affected by extreme heat,

cold or the elements. The selected installation area must be adequate

for easy service and accessibility.

• This system is designed to treat cold water only. The installation must

be on a cold water supply.

Data Chart for ION-X 2000 V Resin

*

Cation Exchange Media

Higher or lower pressure will affect the

efficiency of the system.

If the iron content of the water to be soft-

ened is zero, and the hardness level is

less than 20 gpg, we suggest you choose

the low salt setting for the most efficient

operation. Please go to page 13 for the

instruction of how to set the pounds of

salt.

Important Note: This system

requires the use of the supplied

transformer (24 VAC).

Model

Tank Size

(inches)

Resin*

(cu. ft.)

Service

Flow

(gpm)

Drain

Flow

(gpm)

psi Drop

High

Salting

Medium

Salting

Low

Salting

TC 50 V

8 x 44

0.5

10

1.5

14.0

17,400 @

7.5 lbs.

14,200 @

5.0 lbs.

6,600 @

1.5 lbs.

TC 50 CV

8 x 44

0.5

10

1.5

13.0

17,400 @

7.5 lbs.

14,200 @

5.0 lbs

6,600 @

1.5 lbs.

TC 60SS V

10 x 18

0.6

9.5

2.0

9.0

19,000 @

9.0 lbs.

15,500 @

6.0 lbs.

7,200 @

1.8 lbs.

TC 60SS CV

10 x 18

0.6

9.5

2.0

8.0

19,000 @

9.0 lbs.

15,500 @

6.0 lbs.

7,200 @

1.8 lbs.

TC 60S V

10 x 35

0.6

9.5

2.0

9.0

19,000 @

9.0 lbs.

15,500 @

6.0 lbs.

7,200 @

1.8 lbs.

TC 60S CV

10 x 35

0.6

9.5

2.0

8.0

19,000 @

9.0 lbs.

15,500 @

6.0 lbs.

7,200 @

1.8 lbs.

Important Note: The manually

operated bypass valve enables

the conditioner to be isolated

from the water service line for

maintenance and service. It

also maintains the continuity of

the water supply when the

conditioner is disconnected.

Summary of Contents for TC 100 CV

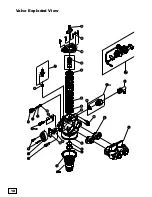

Page 18: ...18 18 Valve Exploded View ...

Page 20: ...20 Control Exploded View 20 ...

Page 23: ...23 Notes ...

Page 44: ...44 Vista despiezada de la válvula ...

Page 46: ...46 Vista despiezada del control ...

Page 49: ...49 Notas ...

Page 50: ...50 Notas ...

Page 51: ...51 Notas ...