39

Radijator Inženjering d.o.o, 36000 Kraljevo, Živojina Lazića - Solunca br.6, Srbija

tel. +381 36 399 140, fax. +381 36 399 150, http://www.radijator.rs

The basic two parameters which the user regulates based on the type of fuel and flame intensity are:

the time needed to supply fuel into the furnace button 9 and the fan’s power (rotation per minute)

button 8

These two parameters, at all times, have to be in such correlation that the combustion process is always

done at the top of the furnace. The combustion should be such that there is no fuel spilling out of the

grey cast iron furnace nor returning flames toward the silo.

It is possible to set the combustion in the boiler correctly in about an hour. It is ungrateful to state the

approximate values of these parameters due to different conditions when starting the boiler.

Starting the boiler on solid fuel

In case that the user prefers the boiler working on solid fuel, the following steps should be done:

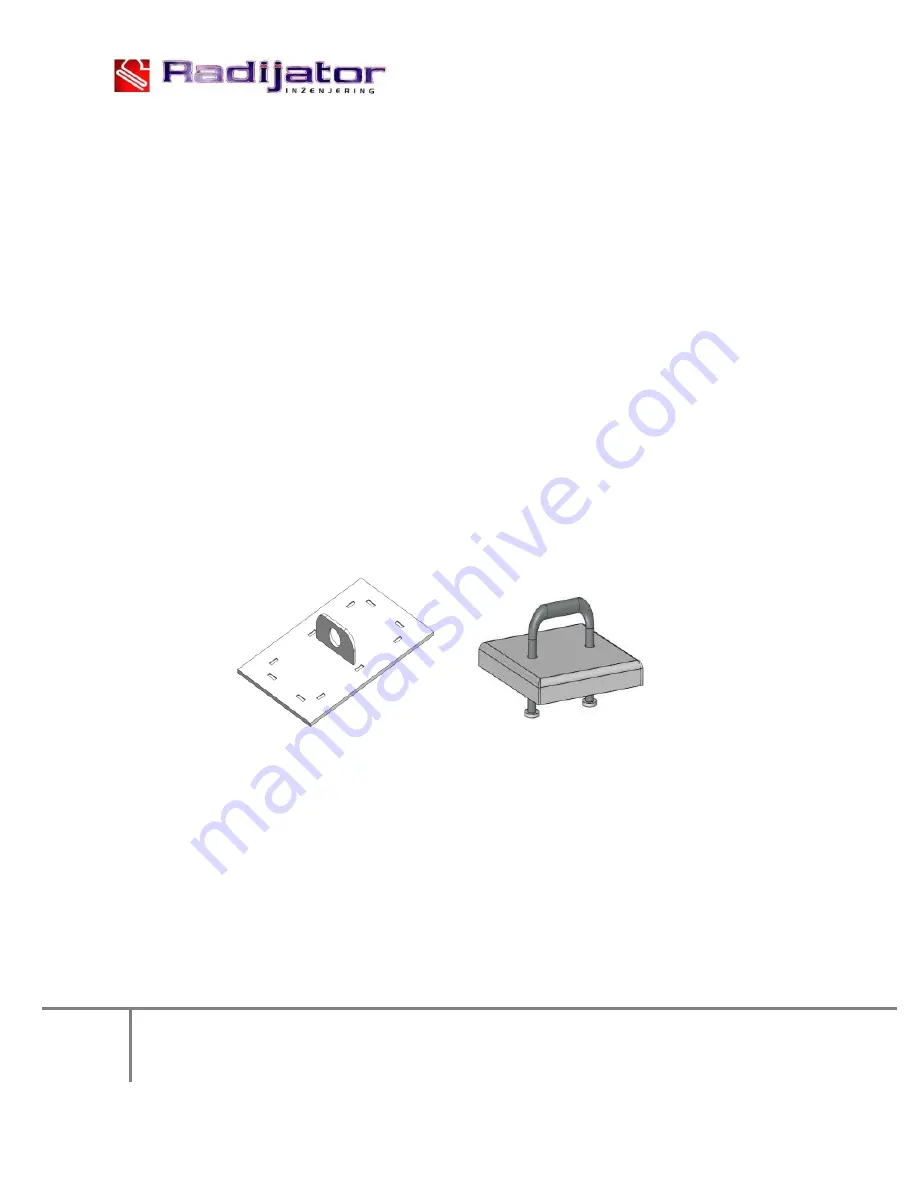

Place supports for iron grates as well as grates of grey cast iron in the boiler’s furnace. This is the

additional equipment and these parts should be separately ordered. This entire assembly is

completely disassemblable as seen in picture 16

.

Put the ignition fuel on grates and ignite manually. When flame appears turn on the ‘Wood’ mode

in automatic controls. If the boiler was previously in the ‘Pellets’ mode turn this mode off.

In the ‘Wood’ mode, combustion is done by air coming from the fan being used during firing

with pellets as well. The air itself passes through the pellets furnace so that this space mustn’t be

covered with ash dumps or any other protections.

Picture 16. The representation of the lid which covers the chamber where pellets come out and which covers the chamber of the

screw which leads ash into bins