Installation Manual

Wall Hung Boiler with D.H.W. Storage Cylinder Low Nox – Cod. 99881NA – July 2001

24

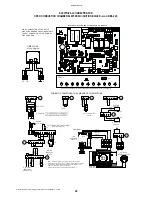

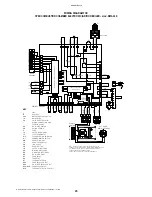

ELECTRICAL CONNECTION FOR

ROOM SEALED COMBUSTION CHAMBER ELECTRONIC IGNITION BOILER – mod. RMAS 24 E

M4

M1

M5

M6

m1

RL1

GAS VALVE

PRESSURE

MODULATOR

42 41

44

46 45

47

48

43

M10

bl

ue

br

ow

n

bl

ac

k

bl

ac

k

bl

ac

k

M.F.

M9

WATER

SWITCH

back

bl

ue

br

ow

n

FA1

PRESSURE

3

C

2

CONTROL

REMOTE

-IN

+

REMOTE SENSOR

TEL

00.0

SEX

T

2

1

M1

00.0

OR TA

OUT-DOOR

2

1

3

m3

IGNITION

OPTIONAL

P.C.B.

N

12

11

10

9

7

8

LB

13

L

L

PS

INTERFACE

N

REMOTE

bl

ac

k

bl

ue

lg

ht

-b

lu

e

brown

br

own

TERMINAL BLOCK

TS

5

12

6

7

8

9

10

11

4

ELECTRONIC IGNITION S4565A20

ELECTRODE

N

L

ATTENTION:

lig

ht-

bl

ue

lig

ht-

bl

ue

RED

CX

FILTRO

NET FILTER

CY

CY

PUMP

P

IG

R

br

ow

n

br

ow

n

M8

or

an

ge

or

an

ge

m2

V

5+ 4-

Z

brown

bl

ac

k

bl

ac

k

red/black

brown

8 7

28

27

26

25

10000 - 25°C

black

E.I

black

black

SENSOR

D.H. WATER

DIVERTOR

AIR PRESS.

SWITCH

FAN

black

31

33

32

34

black

SENSOR

HEATING

VALVE

10000 - 25°C

C

B

6

lig

ht-

bl

ue

lig

ht-

bl

ue

5

4

3 WAY

A

br

ow

n

bl

ac

k

bl

ac

k

br

ow

n

RLA

D4

48

60

B

A

M. RIS

T. RIS

63

31

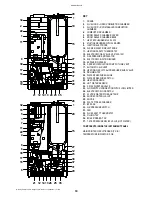

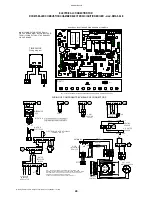

RAVI 2 CIRCUIT BOARD-ELECTRONIC TEMPERATURE INDICATOR WITH SELF-DIAGNOSTIC

WIRING OF COMPONENTS BY MEANS OF CONNECTORS

23

LED5

C6

C7

RS1

R58

R22

R21

4

2

1

3

15

14

22

LED2

LED1

LED3

LED4

RAVI II

R31

42

R18

R17

yellow

blue

R48

FA1

C2

0

R49

R23

R24

R47

C1

9

C2

1

red

brown

R39

C9

M9

R62

R61

R57

J16

R38

+

C5

J20

R37

41

R16

C14

IC2

+

J7

T4

1

2

3

5 4

GP

L

C1

5

R40

R56

ME

T

R43

R33

R15

R32

43

C13

+

C26

R42

44

45

R41

47

J21

R36

46

D1

2

61

R34

24

17

16

18 19

21

20

LED8

LED6

LED7

LED9

LED10

LED11

J2

M1

D2

8 7 6 5

J3

3

4

2 1

35

36

+

C8

J9

C3

R12

R13

+

40

38

IC1

M10

J15

39

37

J13

R5

R2

R20

C1

2

C1

0

J18

M8

CM4

+

34

64

M14

J12

R28

R30

R26

J5

CM3

+

+

+

32

33

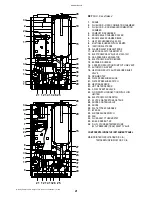

RAMIRE 3 CIRCUIT BOARD STANDARD ON ALL MODELS

D8

N.B. M1 CONNECTOR OF THE RAVI 2

52

53

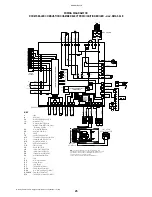

Wiring diagram

+

M13

J10

RISC.

+

C25

R63

R60

59

R59

IC4

P2

TIME CLOCK

M11

D6

49

J11

C24

TR1

D1

1

J1

7

50

51

J6

D1

0

D7

CIRCUIT BOARD MUST BE CONNECTED TO

THE M11 CONNECTOR OF THE RAMIRE 3

CIRCUIT BOARD.

SEC

O

ND

A

R

IO

PR

IM

A

R

IO

57

CM1

RLA

55

54

R55

56

R35

58

IC3

R54

D9

R53

PTC1

25

29

62

P1 SAN.

P4

R29

P5

T1

R25

T3

P3

RL4-RV

D3

D1

T2

R27

J4

D2

M7

30

C22

+

M5

RL2-RS

J2

J4

J1

28

27

24

26

M6

RL1-RP

RL3-RT

R50

R51

D5

M4

14

15

22

M12

23

J3

16

21 20

R52

17

18

19

2AF

FUSE 1

C23

M1

9

M2

13

10

11

12

8

7

3

4

6

M3

5

2

1

N.B.:

IN CASE OF REMOTE CONTROL INSTALLATION, FOR

CORRECT OPERATION, REMOVE LINK BETWEEN TERMINALS TA-OR

ON TERMINAL BLOCK, AND SET SUMMER-WINTER SWITCH OF

CONTROL PANEL ON SUMMER POSITION.

CHECK THE POSITION OF M10 BEFORE I

NSERTING IT.

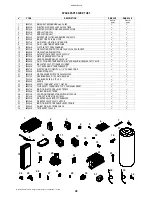

Summary of Contents for RMA

Page 2: ......