Installation Manual

Wall Hung Boiler with D.H.W. Storage Cylinder Low Nox – Cod. 99881NA – July 2001

11

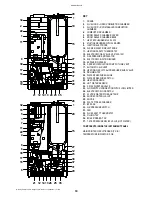

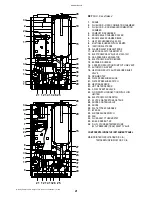

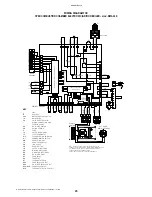

CONTROL PANEL

LEGEND

(see fig. 1)

1.

SUMMER-WINTER ON-OFF SWITCH

2.

LOCK-OUT INDICATOR

3.

HEATING TEMPERATURE ADJUSTMENT KNOB

4.

WATER TEMPERATURE ADJUSTMENT KNOB

5.

SPACE FOR ADDING AN OPTIONAL TIMER

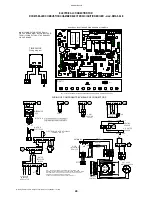

SELF- DIAGNOSTIC

LEGEND (see fig. 2)

6.

OPERATING/ POWER INDICATOR

7.

DOMESTIC HOT WATER OPERATION

8.

HEATING OPERATION

9.

FLASHING LIGHT DENOTING AIR PRESSURE SWITCH FAILURE

10.

FLASHING LIGHT DENOTING DOMESTIC WATER SENSOR FAILURE

11.

FLASHING LIGHT DENOTING HEATING SENSOR FAILURE

12.

FLASHING LIGHT DENOTING 90° C MAX TEMPERATURE SENSOR

FAILURE

13.

FLASHING LIGHT DENOTING FLUE SAFETY - THERMOSTAT FAILURE

14.

FLASHING LIGHT DENOTING LACK OF WATER IN SYSTEM

15.

WATER PRESSURE LEVEL 1 BAR

16.

WATER PRESSURE LEVEL 1.5 BAR

17.

ELECTRONIC TEMPERATURE INDICATOR

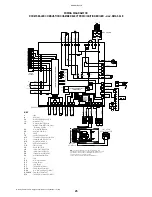

STARTING UP THE BOILER

After connecting up the water supply, before starting up the boiler, carry out the following procedures:

Preliminary procedure

•

Do as follows:

•

make sure the power supply for the boiler is the same as that stated on the plate (230V - 50Hz) and that the live, neutral and

earth connections have been properly connected;

•

make sure the type of gas being supplied is the same as the type for which the boiler has been tested and approved (see

plate data);

•

make sure the unit is properly earthed;

•

make sure there are no flammable liquids or materials in the immediate vicinity of the boiler;

•

make sure that any shut-off valves in the heating circuit are open;

•

open the gas cock and check the gas seals, making sure the counter shows no sign of leaks; in any case, double check by

using a soapy solution and eliminate all eventual leaks. The checking procedure for the gas burner attachment is carried out

with the boiler working;

•

make sure the electrical mains switch is OFF;

•

remove the front cover by pulling it forwards;

•

undo the side screws and rotate the panel downwards

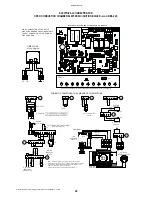

Filling the system

After making sure the gas cock is closed, fill the heating system as follows;

•

fill the system until a pressure of 1.5 bar has been reached (light no. 16 ON; see fig. 2) and then close the filling tap located

under the boiler;

•

make sure the cap on the auto air vent valve is slightly loose to allow air to escape from the system (see fig. 1 pag. 12);

•

undo the cap on the circulation pump to eliminate any eventual air locks (see fig. 1 pag. 13). It is a good idea to purge all

radiators of air at this point too;

•

before starting up the boiler the water pressure must be checked again; if this is seen to be below 0.5 bar (light no. 14

flashes; see fig. 2), bring it back up to 1.5 bar (light no. 16 ON; see fig. 2) and then close the filling tap located ander the

boiler;

•

switch on the electrical power supply to the boiler;

•

turn selector switch 1 to the WINTER

!

position (see fig. 1), after a few seconds the pump will come into action;

•

once the boiler is working, if any noises are heard in the system, repeat the above air purging procedures until there is no air

left in the system;

•

check there are no obstructions in the exhaust duct;

•

check the pressure in the system: if this has gone down and LED 16 (see fig. 2) comes on (pressure gauge shows 1.5 bar)

restore pressure

•

close the filling tap once this operation is completed;

6

7

1

17

10

8

9

11 12 13 14

15 16

2

3

4

5

50

30

40

60

70

80

1

1.5

PRESSURE GAUGE

ELECTRONIC WATER

SELF DIAGNOSTIC

Fig. 1

Fig. 2

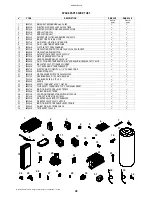

Summary of Contents for RMA

Page 2: ......