We reserve the right to make technical changes.

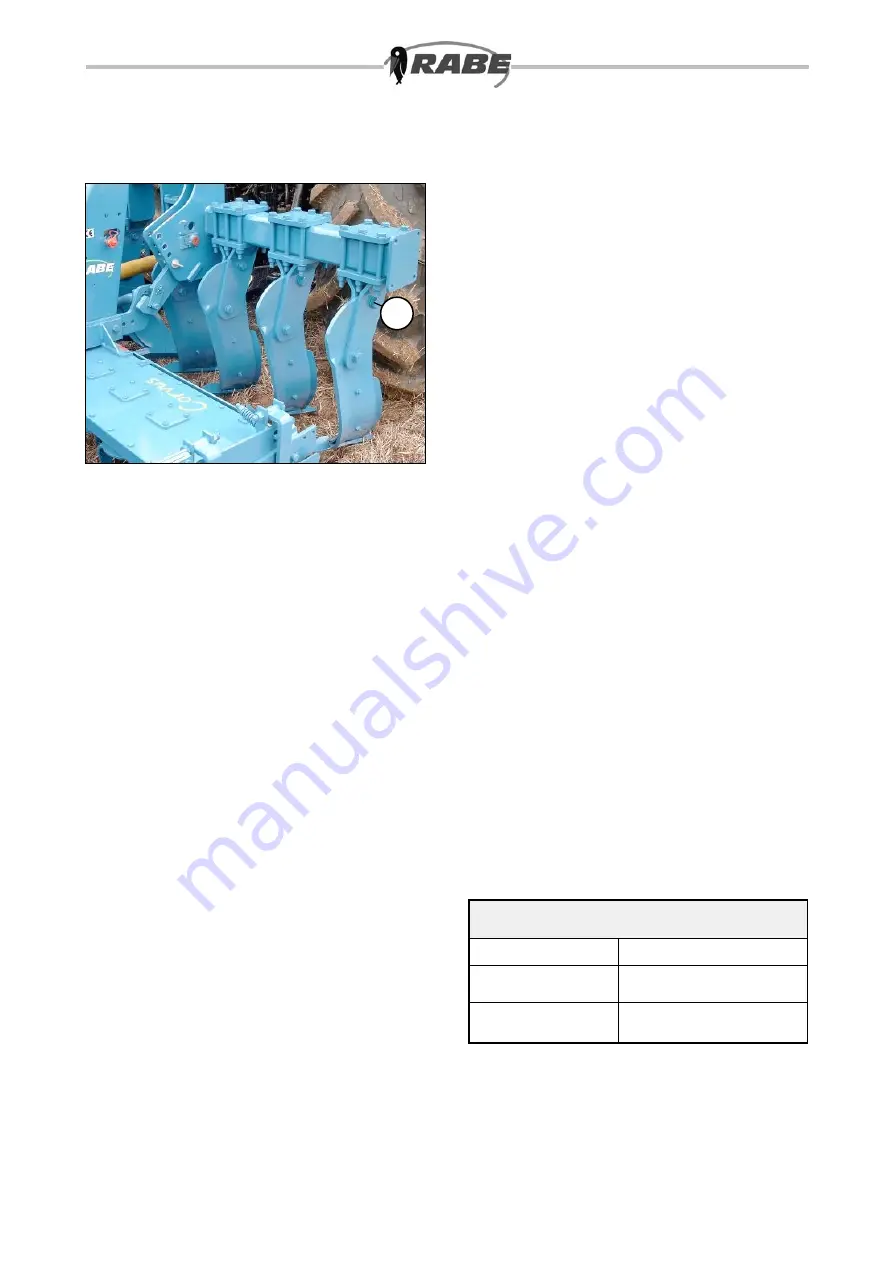

Shearing-pin safety device

The lower one of the two screws (5/1) used to

secure the tines to the tine holder is configured

as a shearing pin to protect against overloading.

If it breaks, a new original screw (M24x1.5x X,

strength rating 8.8) must be fitted. The upper screw

should also be checked for damage, and replaced

if necessary.

5

1

Servicing

Switch off the engine and remove the ignition key

before working on the attached implement. Do not

work under a non-secured raised implement.

Provide the raised device with additional support to

prevent accidental dropping. Before working on the

hydraulic system, lower the device and release the

hydraulic pressure.

After approximately eight hours of operation from

initial startup, retighten all screws and bolts, then

check for tightness at regular intervals.

Lubricate all bearings regularly with a grease gun

applied to the greasing nipples. Hose conduits are

subject to a natural ageing process and should in

any case be replaced after 5-6 years, regardless of

their apparent condition.

Residual risks

Danger zone

Note

Shut down the

entire device

Operating Instructions:

Attachment and removal

Connection of the

complete device

Operating Instructions:

Safety precautions

5