18

We reserve the right to make technical changes.

8. Maintenance instructions

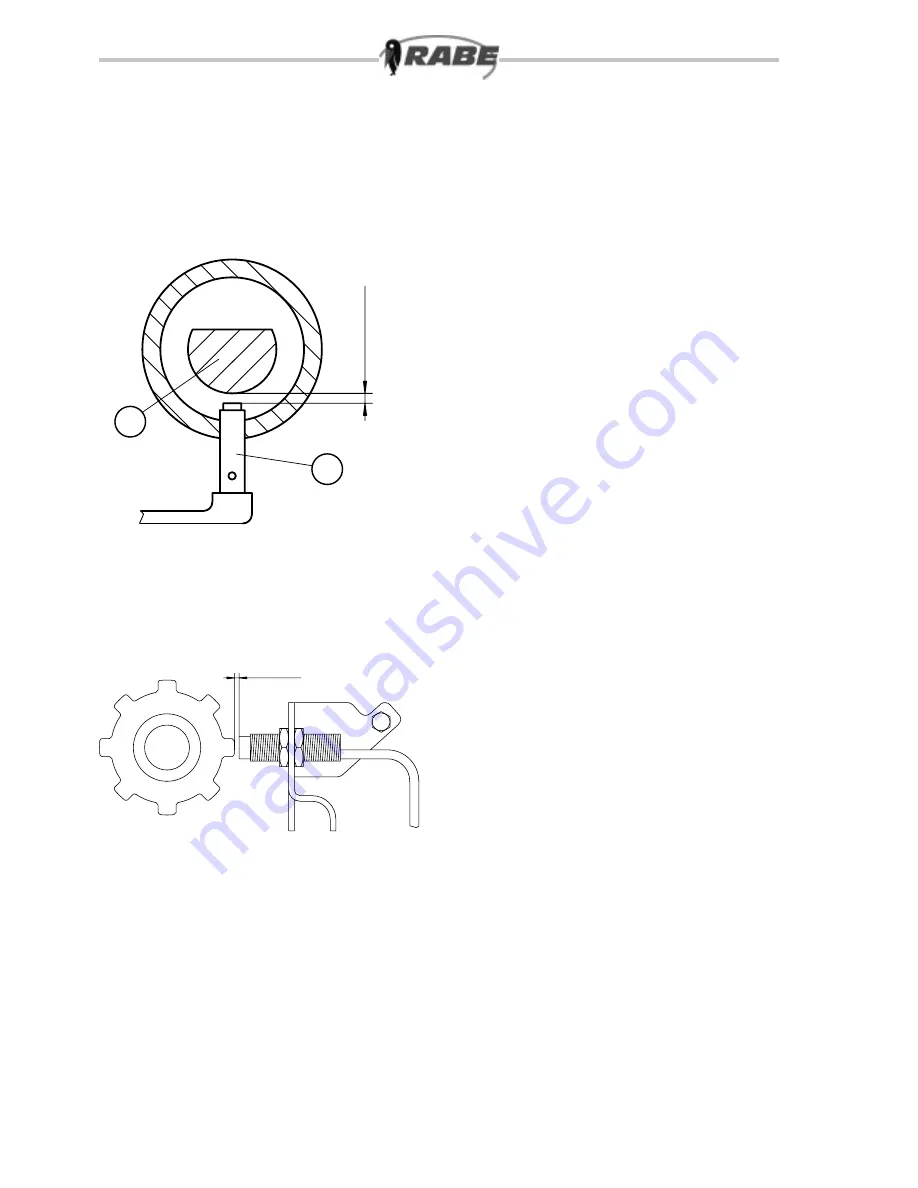

Sensor adjustment: The inductive sensors are set to a

gap of 1-3 mm. To adjust the fan sensor (18.1/1), pro-

ceed as follows: Rotate the fan shaft (18.1/2) so that the

shaft groove is not aligned with the threaded hole of the

sensor. Rotate the sensor by hand up to the fan shaft,

then rotate it back by 3½ turns and lock with the nut. The

sensor is fitted with an LED function indicator so that

“Function of sensor” is displayed whenever a correction

adjustment or test activation takes place.

Use a soft cloth and mild household detergent to remove

any dirt from the drill computer-box (DO NOT use sol-

vents).

DO NOT immerse the housing in liquid.

Disconnect all wires to the electronic terminal box before

carrying out welding work on the tractor or attached

devices, or when charging the tractor battery or connec-

ting a second battery (for carrying out a jump-start).

Given the hygroscopic characteristics of seed (including

dressing agent), the hopper (and dosing wheels) should

be emptied before a long period without operation. Run

the blower briefly to complete the emptying of the seed

conduits. After cleaning, leave the emptying outlet and

rotating cover open, so as not to attract rodents and

other pests. When carrying out cleaning operations,

note that dressing agent is a toxic irritant. Protect such

sensitive parts of the body as the mucous membranes,

eyes and respiratory organs. Do not allow earth or mud

to dry on the coulters. Apply a grease gun to the lubrica-

tion nipples of the bearings at regular intervals (i.e. every

100 hours). A toothed pressure roller will remain in good

condition if it is cleaned after each operation and pro-

tected from corrosion.

Park the Aquila machine in a dry, undercover location,

with its coulters and lane discs clean and protected to

prevent corrosion. Protect the electronic terminal box

(with connection cables) from moisture and store in a dry

place.

Cover the plug socket for the supply cable loom (to

protect from possible soiling). Check the hydraulic hose

conduits at regular intervals and replace any damaged

or brittle items (see list of spare parts). Hose conduits

are subject to a natural ageing process and should be

replaced at intervals of no more than six years. Avoid

directing the hose at the bearings for any length of time,

especially when cleaning the implement with high-pres-

sure water. (The inductive sensors on the monitoring

devices are set to a gap of 1 - 3 mm (18.2). The sensor

is fitted with an LED function indicator so that “Function

of sensor” is displayed whenever a test activation takes

place. For details of sensor adjustment, (see mainte-

nance instructions).

1 - 3mm

18.2

1 -

3

m

m

18.1

1

2