Press and hold the Tig torch switch to start sequence.

The machine will open gas valve to start flow of shield gas, after a 0.5 seconds pre-flow time to purge air from

torch hose the welding output of machine will be turned on and the arc will be started. After the arc is started the

output current will increase from the start (min) current to base (main) current in time selected by slope-up.

Release the Tig torch switch to end sequence.

The machine will now decrease output to finish (min) current in time set by slope-down, once at finish (min)

current the machine will stop output and the gas valve will continue to operate for the selected time (post flow)

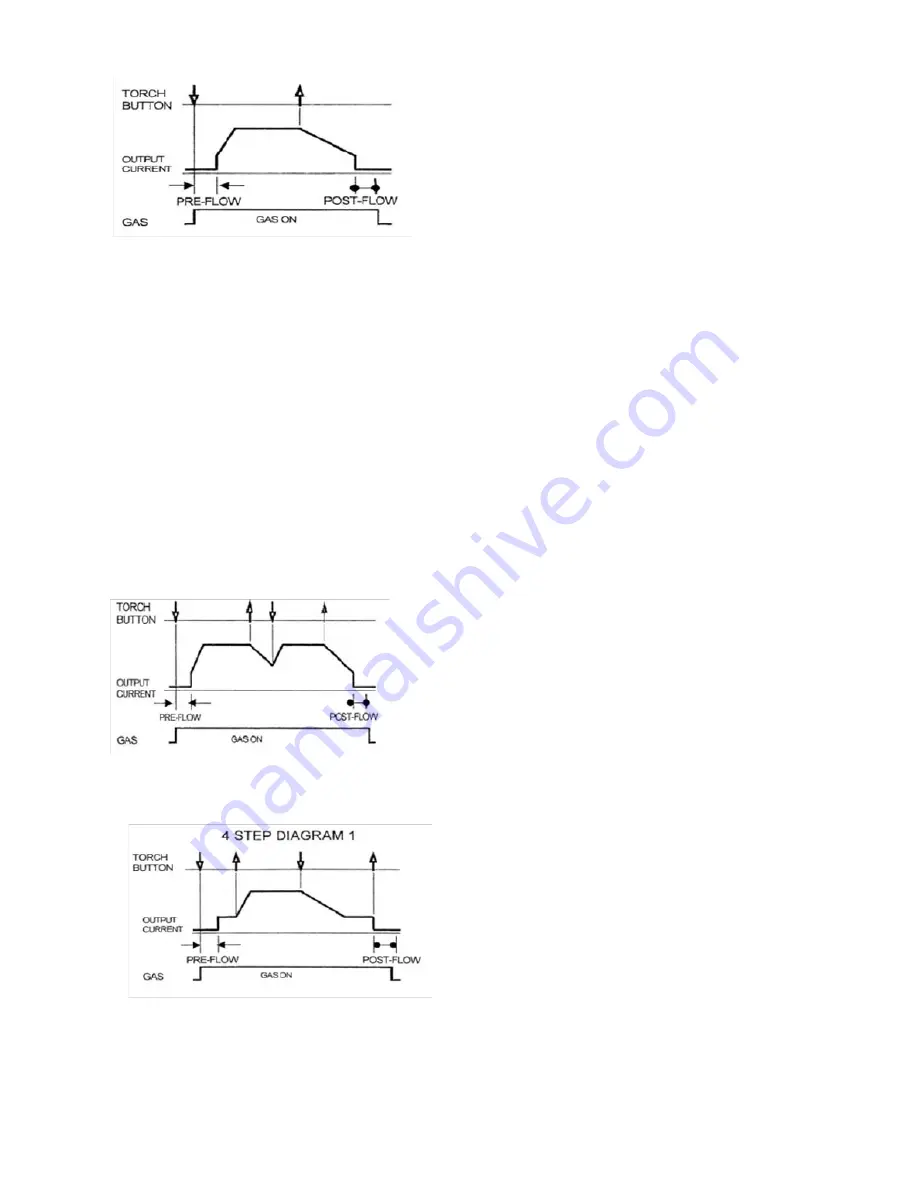

Possible variations of this standard sequence are shown in diagram below. It is possible to press and hold tig

torch switch a second time during down slope time to restart. After the switch is pressed the output current will

raise to base (main) current

When the trigger mode is in the 4 step position the following sequence will occur

Press and hold the tig torch switch to start sequence.

The machine will open gas valve to start flow of shield gas, after a 0.5 seconds pre-flow time to purge air from

torch hose the welding output of machine will be turned on and the arc will be started. After the arc is started the

output current will be at start (min) current

12

Summary of Contents for TIG200PDC

Page 2: ...2...

Page 19: ...Wiring diagram 19...