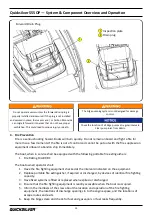

Quicksilver 555OP — System & Component Overview and Operation

13

engine(s) have been tested to perform with the maximum level of ethanol blended gasoline (10%

ethanol), currently allowed by the EPA in the United States.

Special precautions should be considered with the use of fuel containing ethanol in your system. Fuels

with ethanol can attack some fuel

-

system components, such as tanks and lines, if they are not made

from acceptable ethanol

-

compatible materials. This can lead to operational problems or safety issues

such as clogged filters, leaks, or engine damage.

Your boat was manufactured, and shipped from the factory with ethanol compatible materials. Before

introducing petrol with ethanol into your fuel tank, ask your dealer if any components have been

added or replaced that are not recommended by Quicksilver®, Mercury or may not be ethanol

-

compatible.

Filling The Tank

It is best to maintain a full tank of fuel when the engine is not in use. This will reduce the air flow in

and out of the tank due to changes in temperature as well as limiting exposure of ethanol in the fuel

to humidity and condensation.

When filling the tank, do not attempt to top off the tank. When the nozzle shuts off, the tank is full,

and continuing to fill past the fuel fill shutoff will cause the system to spit fuel back.

Phase Separation

Humidity and condensation create water in your fuel tank which can adversely effect the ethanol

blended fuel. A condition called phase separation can occur if water is drawn into the fuel beyond the

saturation point. The presence for water in the fuel beyond the saturation level will cause most of the

ethanol in the fuel to separate from the bulk fuel and drop to the bottom of the tank, significantly

reducing the level of ethanol in the fuel mixture in the upper level (phase). If the lower level (phase),

consisting of water and ethanol, is deep enough to reach the fuel inlet, it could be pumped directly

into the engine and cause significant problems. Engine problems can also result from the reduced

ethanol/fuel mixture left in the upper phase of the tank.

Additives

There is no practical additive known that can prevent or correct phase separation. The only solution is

to keep water from accumulating in the tank. If phase separation does occur, your only remedy is to

drain the fuel, clean and dry the tank completely and refill with a fresh, clean tank of fuel.

Fuel Filters

Mercury already provided the appropriate level of filtration to protect the engine from debris. The

addition of another in

-

line filter to the system will create a possible flow restriction that can starve the

engine of fuel. As a precaution, it is advisable to carry extra on

-

engine filters in case filter plugging

from debris becomes a problem during boating.

Maintenance

Periodically inspect for the presence of water in the fuel tank. If any is found, all water must be

removed and the tank completely dried before refilling the tank with any fuel containing ethanol.

Do not store any equipment containing petrol (outboard

engines, portable petrol tanks, etc.) in any cockpit storage

areas, unless it has adequate ventilation as specified by

Quicksilver®.

Petrol vapors can explode. Never smoke while handling or

filling up the petrol tank. Leaking fuel is a fire and explosion

hazard. Inspect the fuel system annually to make sure that

there are no leaks and corrosion in the system.

Summary of Contents for Activ 555

Page 1: ...Activ 555 Open Owner s Manual ...

Page 2: ......

Page 16: ...Quicksilver 555OP General Information 4 6 Safety Label Locations ...

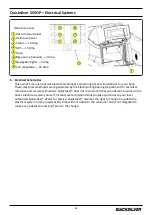

Page 41: ...Quicksilver 555OP Electrical Systems 29 DC Wiring Schematic ...

Page 46: ...34 Quicksilver 555OP Maintenance THIS PAGE INTENTIONALLY LEFT BLANK ...