QBD COOLING SYSTEMS INC.

QBD.COM

27

-

Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

-

Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

-

Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

venting procedure begins or use hoses

long enough to discharge it safely to

outside environment.

-

Attach gauges to both the high and low

sides of the system using an approved

method.

-

To

avoid

accidental

release

of

refrigerant and lubricant, ensure that

they are recovered/ vented safely from

the system before removing the failed

component of the sealed system.

-

Always recover the refrigerant from both

high and low sides of the system to

assure that no refrigerant is trapped in

the system.

-

Purge the system with Oxygen Free Dry

Nitrogen (OFDN) several times to

ensure complete removal of refrigerant

from refrigeration system.

-

Achieve a 500 micron vacuum in the

refrigeration system using a certified

vacuum pump before replacing failed

sealed system component(s).

-

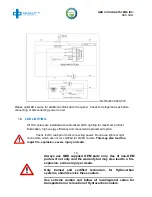

Use a tube cutter rather than a torch to

remove the failed component as shown

below. Using a torch may cause a fire

hazard, especially if the refrigerant has

not

been

completely

discharged/

recovered. If you must use a torch to

remove the failed component of sealed

system, do so while running dry nitrogen

continuously through the system.

Always use OEM parts only. Use of non-

OEM parts will not only void the warranty

but may also lead to a major fire,

explosion, severe injury or death.

Pressure Testing and Evacuation

-

Pressurise

the serviced refrigeration

system with oxygen free dry nitrogen

(OFDN) up to 150 psig.

-

Hold the pressure and check for

possible leak.

-

Purge

OFDN

before

starting

the

evacuation process.

-

Never use a compressor to evacuate a

system. Use a certified vacuum pump

with manifold gauges and initiate

evacuation..

-

The discharge of the vacuum pump

must be vented to an open-air area.

-

Ensure the refrigeration system holds a

vacuum pressure of at least 100 micron

before charging.

-

Never attempt to start the compressor

while the system is under vacuum.

-

Always break a vacuum with refrigerant

charge before starting the compressor.

Charging refrigerant

-

Do not overcharge the refrigeration

system

(maximum 150 grams or 5.3

oz.) as per UL#471. Overcharging is a

safety hazard.

-

Use only recommended type and

amount of refrigerant as indicated on the

serial label