DURAWATT

®

ELECTRIC WATER HEATER

PV500-6 09/07

8

Sediment / Lime Scale Removal

Waterborne impurities consist of the particles of soil and sand which settle out and form a layer of sediment on the bottom

of the tank and adheres to heat exchange surfaces. The amount of calcium carbonate (lime) released from water is in

direct proportion to water temperature and usage. The higher the water temperature or water usage, the more lime

deposits are dropped out of the water. Lime accumulation not only reduces the life of the equipment but also reduces

efficiency of the heater.

T & P Relief Valve

The pressure relief valve should be checked at regular intervals by manually opening the valve. The openings inside the

valve may become restricted by a buildup of scale and become inoperative. If the valve does not open and close properly

and does not blow off internal pressure when tested, it must be replaced. Shut down heater, relieve internal pressure and

replace relief valve with a like kind or one meeting the requirements stated on the rating decal located adjacent to the

relief valve mounting location.

Low Water Cut-Off

The standard low water control is electronic. Inspection should be made of the electrode on water heaters equipped with

electronic low water devices.

Electrical Connections

Check all

electrical connections

approximately one to two weeks after initial start-up to assure tightness. Heating and

cooling from operation can loosen connections. Visually inspect wire terminal points for any discoloration on a monthly

basis. Discoloration is likely due to a loose connection at the point nearest discoloration. Check

Contactors

periodically

and clean if necessary and repair or replace pitted points caused by foreign particles. Check

Fuses

periodically for

continuity and replace if necessary with the same dual-element type.

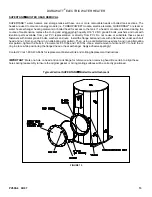

REPLACING ELECTRIC ELEMENTS

Some electric heating elements installed in dished heads may be factory bent to allow clearance from adjacent elements.

Replacement elements must be identical to the original equipment installed. The

Bend Angle

Stamp #

is required for all

replacement electric element requests.

Important:

Install the element facing away from the center of the head.

FIGURE 4

BEND ANGLE

STAMP

25° #1

18° #2

FIGURE 4

Note: No stamp on element flange means that element is not bent.

Typical Electric Element