Edition from 03.06.2015

5

PLC330.

Multichannel stepper motor driver

www.purelogic.ru

8 (800) 555 63 74

04. Driver functional capabilities

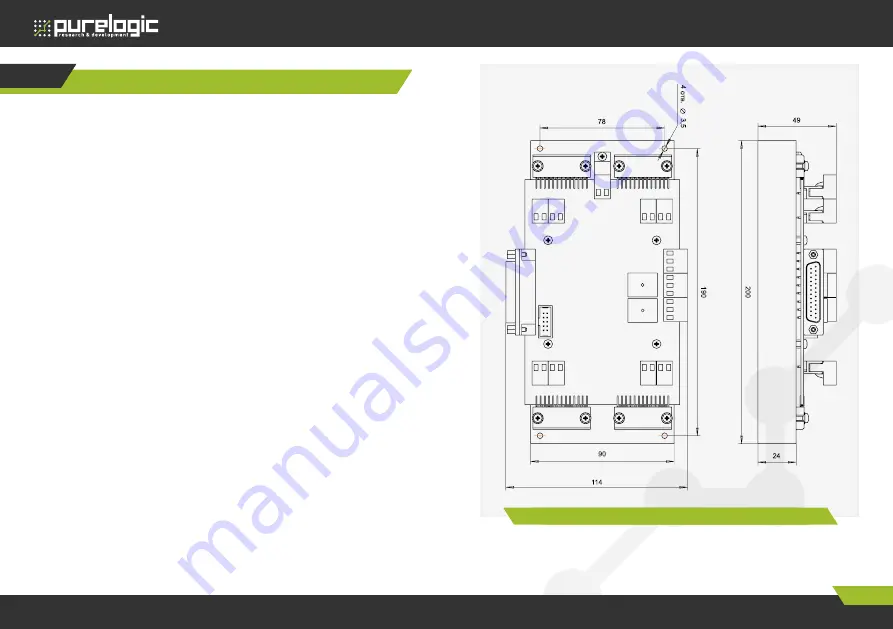

Fig. 1.

Multichannel stepper motor driver PLС330 dimensions

04

Driver functional capabilities

• Operation with any LPT CNC program (STEP/DIR – Mach, TurboCNC

etc.)

• Usage of one supplied voltage for supplying all the scheme, system of

module softstarter.

• Simultaneous control of 4 stepper motors – any bipolar and unipolar

stepper motors (4,6 or 8 outputs) FL57 and others type. We strongly

recommend to use the module with Purelogic R&D stepper motors.

• 4 identical stepper motor drivers (microstep 1:2, 1:8, 1:16, mode

AUTOSLEEP)

Current adjustment in coils of every stepper motor. Fixed PWN

frequency 20 kHz for current control in stepper motor coils.

• AUTO-SLEEP mode automatically reduces current in stepper motor

coils and reduces acoustic noise when in standstill.

• Coil short-circuit module protection, wrong stepper motor connection

protection , polarity reversal supply voltage protection

• Opto-isolation of module and LPT PC port. Current buffering of all

controlling pins of LPT port.

• Control of 2 high current relays 7А/220V and 2 opto-outputs for

commutation of additional machine equipment (spindle, coolant pump

or electric fan).

• Inbuilt regulated timer (time and relay operation duration is

regulated) for commutation of a coolant pump.

• Operation support of frequency converter (regulation of spindle

rotation, PWN converter>voltage), from MACH.

• Control of 5 external sensors state (limit switches) All the inputs are

optoisolated.

• Convenient dismountable clip connectors to step motor, power source

and relay loads.