PUREGAS, LLC

P200W2 Series Dehydrator User’s Guide

Page 14 of 82

P012213 – Rev. F

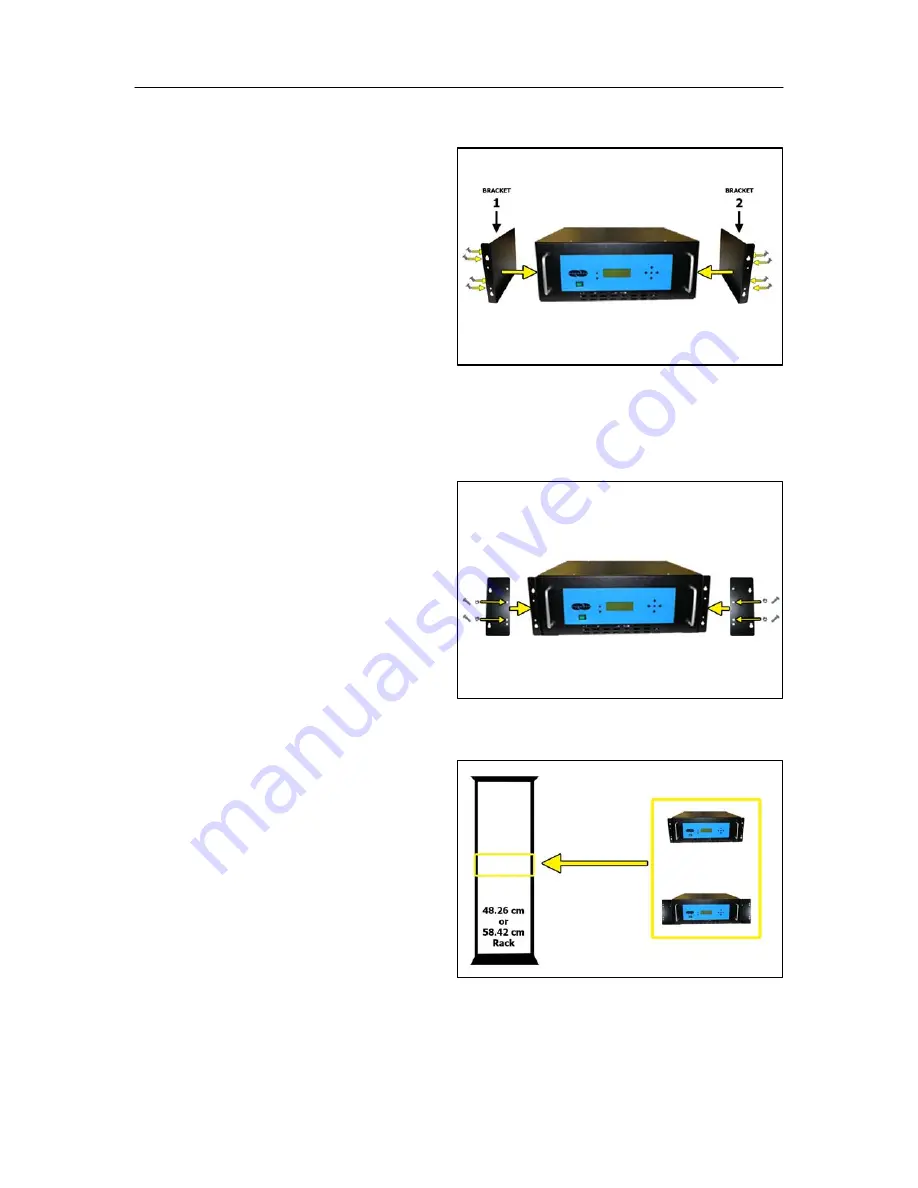

For Rack Mounted Installation:

a.

Attach Mounting Brackets

to the Dehydrator with

mounting flanges facing

forward as shown.

Use

Hardware

A

and

Phillips Head Screwdriver.

NOTE

: Mounting Brackets

can be attached in a number of positions; front-to-back. Choose the

mounting position that meets your rack mounting requirement.

b.

For installation on a

58.42 cm rack, attach the

Bracket Extensions to the

Mounting Brackets as

shown.

Use

Hardware

B

, Phillips

Head Screwdriver, and

7/16” Wrench.

c.

Install the Dehydrator on a

48.26 cm or 58.42 cm

Rack.

Use

Hardware

C

and

Phillips Head Screwdriver.