7

8

Installing the Printer and the intelligent Paper Stacker

1-12

Installation of the Consumables

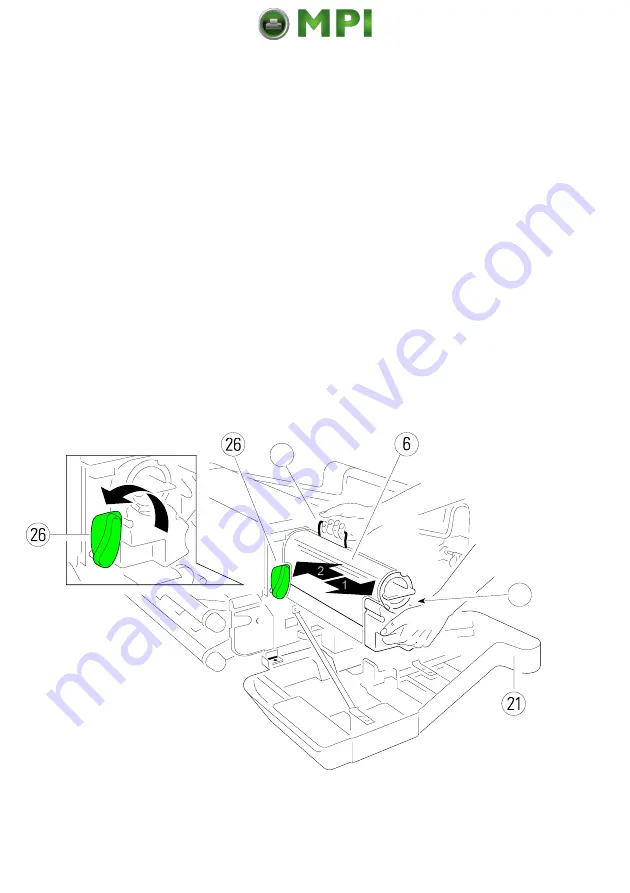

1.5.1 Loading the Developer Unit

$

Lift the lever (26) upwards to unlock the Developer Unit.

$

Pull the Developer Unit (6) about

-

out of the housing and grasp the grip (7)

with one hand and remove it.

$

Remove the plastic bag from the clutch on the rear side.

$

Remove plastic and paper safety strips (8) from the area of the toner output

of the Developer Unit (6).

Note:

Don´t destroy the small plastic lip above the toner output of the

Developer Unit (6).

$

Insert the Developer Unit (6) (step 2.) and secure it by pressing down the

lever (26).