6-9

ROTALIGN 01.2000

Shims

Proper shims must be used for satisfactory alignment results based

upon ROTALIGN shimming corrections.

What constitutes a "proper" shim? First, its thickness must match the

correction values (within 0.025 mm, [1 mil] since shimming stock is

not made thinner than this). The thickness must be consistent over

the whole shim area, without any thick or thin spots. The shim must

be flat, without seams or folds from bending. Burred edges must be

removed or the shim will act as a spring, compressing a bit each time

the foot bolt is tightened, especially when several burred shims are

stacked upon one another. The shim material must be dimensionally

stable, without appreciable cold flow effects when subjected to high

compression over long periods of time. It must also withstand the

demands of the service environment without corroding, since rusty

shims can also act as springs.

Commercial precut shims fill these requirements best, while saving a

major portion of alignment time compared with shims hand cut from

rolls of sheet stock. PRÜFTECHNIK offers two different types of

shims in a wide range of metric thicknesses and sizes to fit most

machine feet. Check with your ROTALIGN dealer for inch thicknesses

and other custom shims.

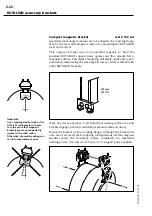

Complete set of shims

PERMABLOC

®

LAMIBLOC

®

Shaft alignment in theory and in practice

PERMABLOC

®

individual stainless steel shims are obtainable in

single thicknesses or as complete sets in their own carrying case. Each

shim is permanently etched (not printed or stamped) with its

thickness. By simply pulling the single shims from the case, the

proper thickness can be achieved in just a few seconds.

LAMIBLOC

®

shims are laminated from 12 layers to give a total

thickness of 1 mm; the correct shimming amount is obtained simply

by peeling off the excess layers. Only a handful of shims are,

therefore, needed at the job site. They may also be ordered as a

complete set in their own case and are available in brass or stainless

steel.

Summary of Contents for ROTALIGN ALI 3.500

Page 13: ...1 10 ROTALIGN 01 2000 This page intentionally left blank ...

Page 103: ...4 66 ROTALIGN 01 2000 This page intentionally left blank ...

Page 121: ...5 18 ROTALIGN 01 2000 This page intentionally left blank ...

Page 143: ...6 22 ROTALIGN 01 2000 This page has intentionally been left blank ...

Page 158: ...6 37 ROTALIGN 01 2000 This page intentionally left blank ...