Protean Instrument Corporation

43

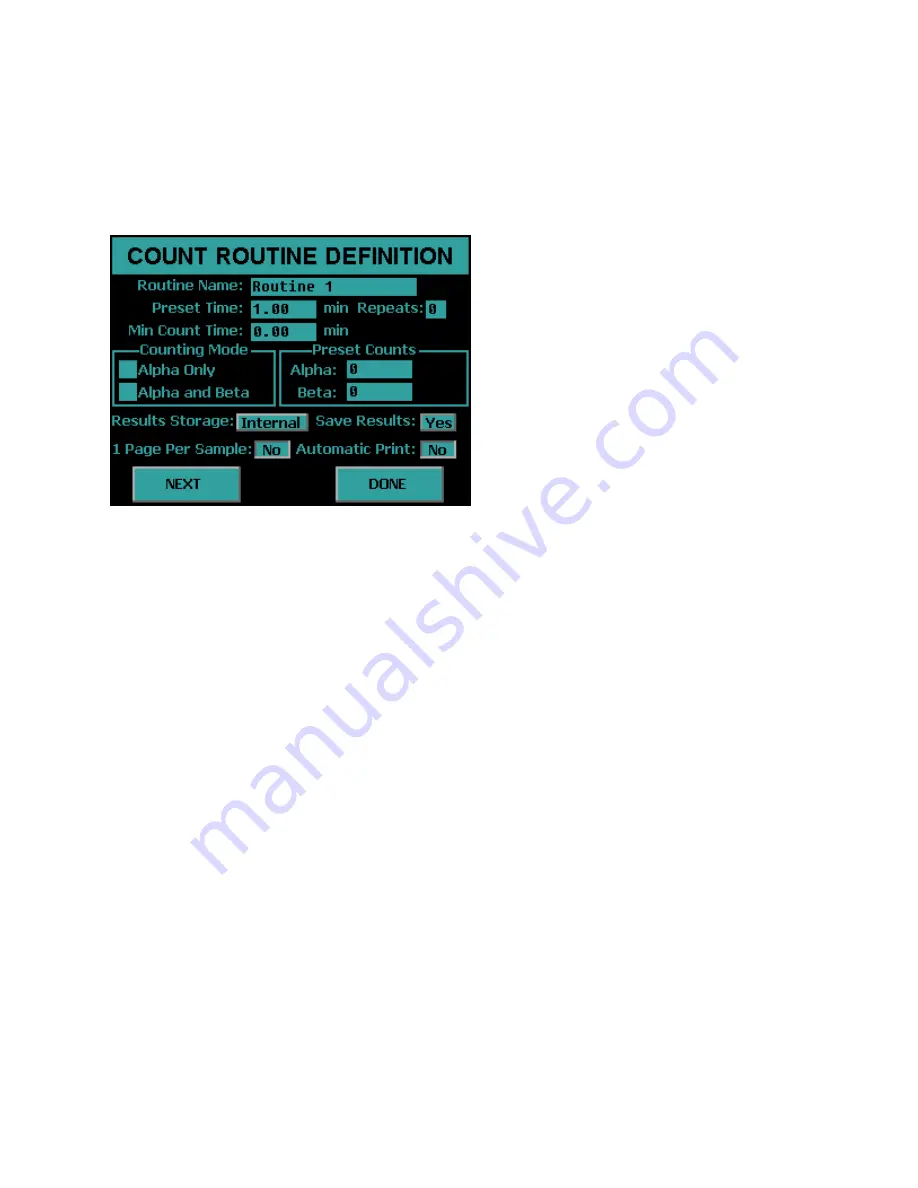

Program MPC

900

Count

Routine

Definition

Page

1

Naming

the

Count

Routine

The name which will appear in the menus for the Count, Data, and Calibration functions

should be defined. This name will identify to the operator the type of samples to be

counted using the defined routine. The name will also appear in the printed report.

Preset

Time

The preset time specifies one of several conditions which can terminate an acquisition.

This field defines the maximum amount of time for sample analysis. For most

applications, this will be the only preset condition that is used. Therefore this time

equates to the amount of time each sample is analyzed. The length of time is usually

selected to meet a desired sensitivity or minimum detectable activity requirement. How

much time is needed should be determined by the worse case efficiency and

background values.

The preset time is set by pressing the

Preset Time

field and entering the time. The

minimum preset time must be greater than 0.01 minute.