Maintenance manual Universal-1000

P R O M E T A L

75

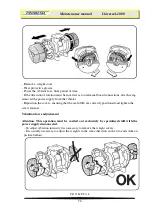

Assure that both unbalance sides are adjusteed in the same direction,

that they show the same marking and that they are positioned firmly

against each other. The two basis unbalances (inner weights) should

in no case be adjusted. Should it be however necessary please assure

that both basis unbalances are mounted in exactly the same position

and unidirectional on the shaft. Furthermore ensure that the basis

unbalance will be pressed firmly against the distance ring.

Warning!

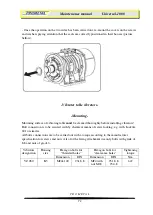

Mark

Centrifugal force

VZ280

N

1 100%

28000

2 90%

25200

3 80%

22400

4 70%

19600

5 60%

16800

The values of the centrifugal force can be adjusted continuously and are allowed for

continuous operation!

-Maintenance Of Vibrators-

General care

The outer housing of the vibrators should be cleaned regularly from strong contaminants.

Housings with cooling fins are to be kept dirt-free in order to secure good heat dissipation.

The cleaning with high pressure steam or high pressure water is not permitted because water

can penetrate into the interior and destroy the electrical winding.

The fixing bolts of the vibrator foot and those of the unbalance covers should be examined for

the right tightening torque and should be re-tightened if necessary. Defective fixing bolts

should be replaced by new screws.

Maintenance

The minimum maintenance plan has to be kept obligatory.

After the first 10 operating hours all fixing bolts and nuts should be examined of their

tightness and if necessary should be tightened or replaced by new bolt connections.

Secured bolt connections (we recommend with Loctite) should not be re-tightened but should

be exchanged and secured again if these have loosened.

The power consumption and the operating temperature of the vibrators should be supervised.

The power consumption shall not exceed the value of the nameplate and the operating

temperature measured on the surface of the motor housing shall not 70°C.

Summary of Contents for UNIVERSAL 1000

Page 19: ...Maintenance manual Universal 1000 P R O M E T A L 19 ...

Page 25: ...Maintenance manual Universal 1000 P R O M E T A L 25 Hydraulic system ...

Page 26: ...Maintenance manual Universal 1000 P R O M E T A L 26 ...

Page 52: ...Maintenance manual Universal 1000 P R O M E T A L 52 Now lower down tamper head and mould ...

Page 53: ...Maintenance manual Universal 1000 P R O M E T A L 53 Pull out cart with mould on itself ...

Page 58: ...Maintenance manual Universal 1000 P R O M E T A L 58 After adjustment is done ...

Page 65: ...Maintenance manual Universal 1000 P R O M E T A L 65 Vibrator table maintenance ...