Maintenance manual Universal-1000

P R O M E T A L

72

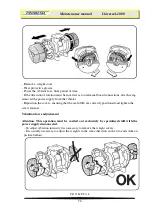

- Once the operation on the two sides has been carried out, re-mount the covers on the screws

and washers paying attention that the seals are correctly positioned in their houses (picture

bellow).

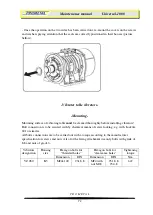

-Vibrator table vibrators-

-Mounting-

Mounting surface of vibrating table

must

be cleaned thoroughly before installing vibrators!

Bolt connection is to be secured with by chemical means of screw locking, e.g. with Locktite

601 or similar.

All bolts connections are to be carried out with a torque according to the manufacturer

specification for screws and nuts. Also for the fixing attachment use only bolts with grade of

8.8 and nuts of grade 6.

Vibrators

designation

Housing

size

Hexagon bolts for

“

threaded holes

”

Hexagon bolts for

“

cleareance holes

”

Tightening

torque

Dimension

DIN

Dimension

DIN

Nm

VZ 280

K5

M24x100

931 8.8

M24 with

nut M24

931 8.8

934-8

647

Summary of Contents for UNIVERSAL 1000

Page 19: ...Maintenance manual Universal 1000 P R O M E T A L 19 ...

Page 25: ...Maintenance manual Universal 1000 P R O M E T A L 25 Hydraulic system ...

Page 26: ...Maintenance manual Universal 1000 P R O M E T A L 26 ...

Page 52: ...Maintenance manual Universal 1000 P R O M E T A L 52 Now lower down tamper head and mould ...

Page 53: ...Maintenance manual Universal 1000 P R O M E T A L 53 Pull out cart with mould on itself ...

Page 58: ...Maintenance manual Universal 1000 P R O M E T A L 58 After adjustment is done ...

Page 65: ...Maintenance manual Universal 1000 P R O M E T A L 65 Vibrator table maintenance ...