5

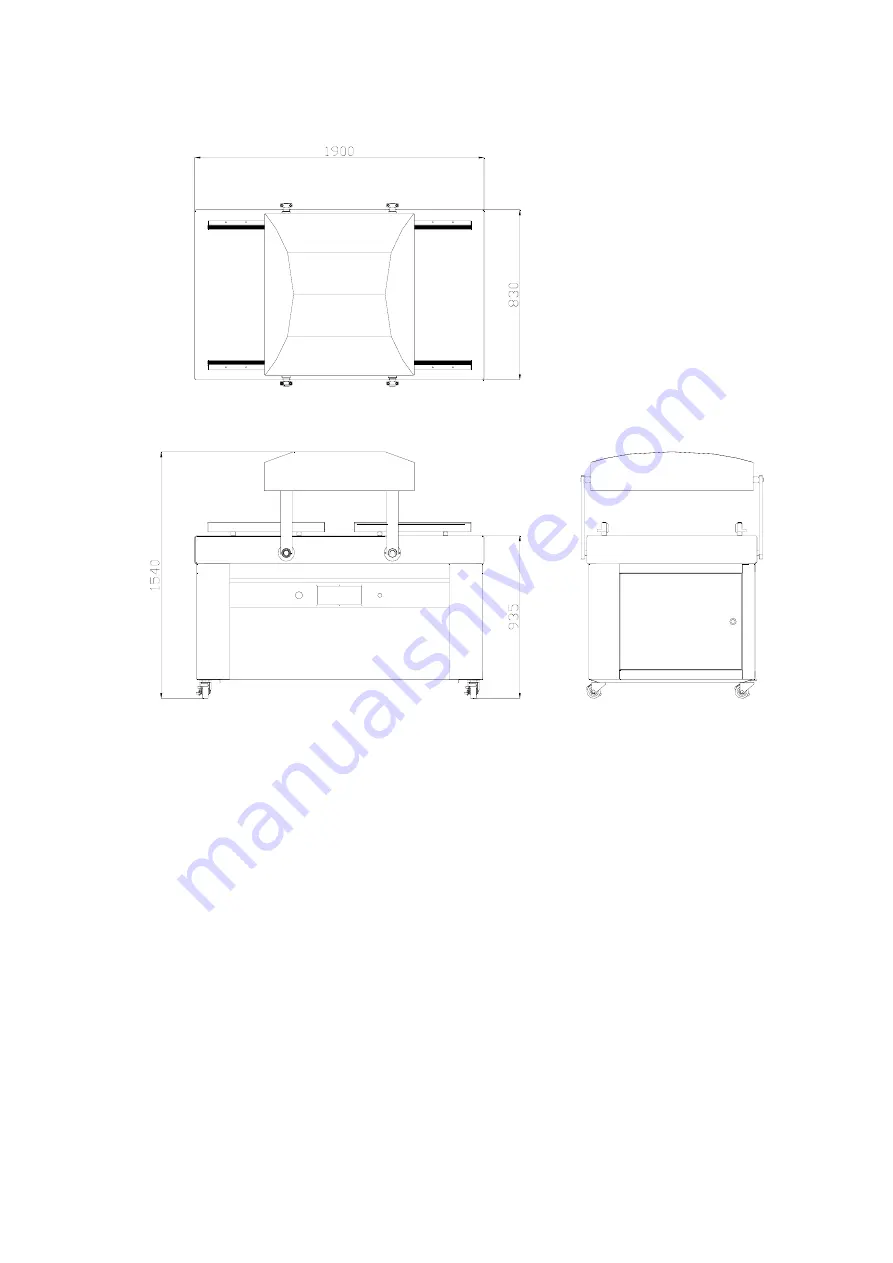

2.3 DC-800 SPECIFICATION

2.4 ENVIRONMENT EQUIREMENTS

The machine will be difficult to start if the air temperature is very low. This is caused by the

increase in the vacuum pump’s oil viscosity due to the low temperature. To prevent this, please set

up machine according to the installation checklist described as below:

z

Temperature:

around 5 ~ 40

℃

z

Working elevation:

between 0 ~ 1000 meters

z

Relative

humidity:

30

~

95%

RH

z

During operating, heat is generated by the vacuum pump and vacuum process, so a

machine temperature of around 70 ~ 80

℃

is normal. The machine must have free air

access for cooling.

z

A minimum distance from walls, other machines, etc. should be maintained, at least 20 cm for

each side of machine for providing adequate ventilation.

Summary of Contents for DC-800

Page 19: ...16 ...

Page 23: ...20 5 3 PNEUMATIC DIAGRAM ...

Page 24: ...21 5 4 ELECTRICAL DIAGRAM FB ...

Page 25: ...22 5 4 ELECTRICAL DIAGRAM TB ...

Page 27: ...6 1 BODY 24 DC80100000 Body Diagram ...

Page 29: ...6 2 WORKING BED BOTTOM 26 C C Working bed Bottom Diagram DC80200000 ...

Page 32: ...6 3 1 CUSHION BAR FB 29 Cushion Bar Diagram D80K2FB000 ...

Page 34: ...6 3 2 CUSHION BAR FBG 31 D80K2FBG00 Cushion Bar Diagram ...

Page 36: ...6 3 3 CUSHION BAR FBPK 33 D80K2PK000 Cushion Bar Diagram ...

Page 38: ...6 3 4 CUSHION BAR FBPKG 35 D80K2PKG00 Cushion Bar Diagram ...

Page 40: ...6 3 5 SEALING BAR BOTTOM FBTB 37 DC802TB000 Sealing Bar Bottom Diagram ...

Page 42: ...6 3 6 SEALING BAR BOTTOM FBTBG 39 DC802TBG000 Sealing Bar Bottom Diagram ...

Page 44: ...6 3 7 SEALING BAR BOTTOM FBTBPK 41 D80K2TK000 Sealing Bar Bottom Diagram ...

Page 46: ...6 3 8 SEALING BAR BOTTOM FBTBPKG 43 D80K2TKG00 Sealing Bar Bottom Diagram ...

Page 48: ...6 4 CHAMBER LID DIAGRAM 45 Chamber Lid Top Diagram DC80300000 ...

Page 50: ...6 5 1 SEALING BAR TOP FB 47 D80K312A00 Sealing Bar Top Diagram ...

Page 53: ...6 5 2 SEALING BAR TOP PK 50 DC80350A00 Sealing Bar Top Diagram ...

Page 56: ...53 6 6 ELECTRICAL BOX FB 6 6 ELECTRICAL BOX TB ...