13

pressure to keep the bit cutting.

Do not force the drill bit or apply

sideways pressure to elongate the

hole.

WARNING: Be prepared for

binding and bit breakthrough.

When these situations occur, the

drill bit has a tendency to grab

the workpiece. This action will

kick the drill opposite to the

direction of the drill bit rotation,

and could cause loss of control

when breaking through material

as you complete drilling the hole.

If you are not prepared, this loss

of control can result in serious

injury.

When drilling metals, use light oil on

the drill bit to keep it from overheating.

The oil will prolong the life of the drill

bit and improve the cutting action.

If the bit jams in the workpiece, or

if the drill stalls, release the trigger

switch immediately. Remove the bit

from the workpiece and determine

the reason for jamming.

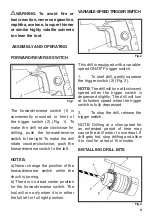

REMOVING THE CHUCK

Fig.8

Fig.9

Fig.10

To remove the chuck:

1.

Remove the drill plug from

the power source.

2.

Insert a 5/16” (8 mm) or

larger hex key (1) into the chuck (2)

and tighten the chuck jaws securely

(Fig. 8). Make sure each of the

chuck jaws (3) is seated on the flat

surfaces of the hex key.

3.

Tap the hex key sharply with

a mallet (4) in a clockwise direction.

This action will loosen the screw in

the chuck for easy removal.

4.

Open chuck jaws and

remove the hex key.

5.

Open the chuck jaws as far

as possible.

6.

Remove the chuck screw

using a #2 screwdriver (Fig. 9).

NOTE: Turn the screw CLOCKWISE

Summary of Contents for PRO-TP800

Page 1: ...1 2 13mm Hammer Drill User s Manual Model No PRO TP800 English 2 I Espa ol 22...

Page 17: ...NOTES...

Page 18: ...NOTES...

Page 19: ...NOTES...

Page 20: ...www promakertools com...

Page 21: ...Taladro Percutor de 1 2 13mm Manual del Usuario Modelo No PRO TP800...

Page 39: ...NOTAS...

Page 40: ...www promakertools com...