Settings

Blade guide settings

The machine has a freely moving lever to alter the

direction by lifting and turning it slightly. It allows you

quickly and easily to adjust the blade guide at any time.

The blade guide is adjusted in accordance with the

dimensions of the parts. Only the one on the left of the

cutting head can be adjusted; the other is fixed.

1. If the part is large, undo lever (A) of Fig. 7. Move the

guide by about 2.5 cm towards the part, then tighten

the lever again.

2. If you are cutting a small part bring the guide as

close as possible to the part. The two types of cut

will guarantee satisfactory accomplishment of the

work.

Adjustment where there is poor

cutting

The machine has been adjusted and subjected to

different cutting tests before leaving the factory to

ensure that it functions properly. If you discover that it is

cutting poorly, correct the defect by doing the following:

1. Poor cutting due to blade wear: put in a new blade.

2. The saw is equipped with fixed ball bearings.

To ensure correct cutting, we recommend to replace

them every three or six months, depending on the

frequency of use.

3. Poor cutting can be due to loosening of the

fastening nut (A). Tighten it again correctly.

Fig. 7

WARNING

Do not make any adjustment and do not load

or unload the part from the vice when the

machine is operating!

Bearing

Maintenance of the gear transmission

The gears of the transmission system fitted to the

machine are made of special steel.

The quality of these gears gives them superior strength

and durability. To keep the saw operating optimally, we

advise you to lubricate them every three months by

carrying out the following procedure:

1. Undo the screw (A) of Fig. 8 using an 8 mm Allen key.

2. Remove the wheel (B), then lubricate the gears

using thermostable grease.

3. Carefully re-assemble the wheel, and tighten the

screw correctly (A).

Fig. 8

Adjusting blade tension

The tensioning system of the machine is designed to facilitate interventions. It is sufficient to turn control lever

(B) of Fig. 6 to increase or reduce the tension of the blade as needed, during operation. The main function of

this adjustment is to ensure perfect cutting as it allows the blade to work at a constant tension. A pair of

compression springs fastened to the tensioning system are there in addition to reduce the play of the blade.

All this contributes to prolonging the lifetime of the latter.

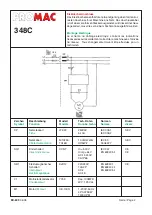

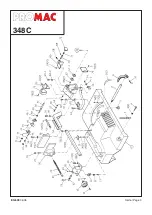

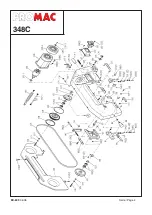

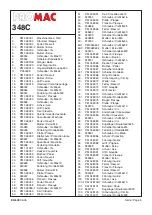

Summary of Contents for 348C

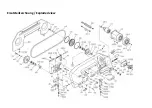

Page 22: ...Ersatzteilzeichnung Exploded view...

Page 23: ...Ersatzteilzeichnung Exploded view...

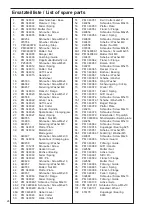

Page 29: ...Seite Page 3 EX 609 06 05 348C...

Page 30: ...Seite Page 4 EX 609 06 05 348C...