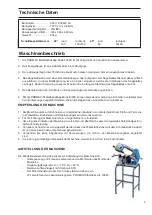

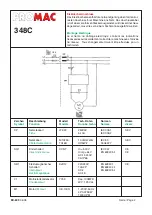

Power supply

Engine Specifications

The direct current motor used on this saw is a non-

reversible

induction

motor

with

the

following

specifications:

Maximum power (kW)

0.38

Voltage (V)

230

Amps (A)

4

Frequency (Hz)

50

Revs (rpm)

1,430

Speed of the blade (m/min)

45

Direction of rotation of the blade drive

shaft to the right

Weight (kg)

23

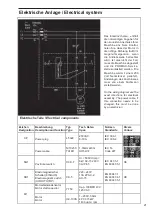

Earthing

This metal hacksaw is a single-insulated tool, the

earthing circuit therefore being designed to protect you

from electrical shocks. The earthing circuit is made once

you have connected the machine to the appropriate

mains power supply. You should therefore provide a

mains power system for this machine that protects you

from electric shock hazard.

Protecting the motor

WARNING:

To prevent any electrical hazard, fire hazard or

damage to the tool, use the appropriate circuit

protection device. Your saw is wired at the

factory to run on 230 V current. Connect it to 10

Amp 230 V mains power supply and use a 10

Amp time delay fuse or circuit breaker. To

prevent electric shock or fire, immediately

replace the power supply cable if it is worn, cut

or damaged in any other way.

DANGER

To prevent electric shock:

1. Only replace the power supply cable and plug

with

identical

models

supplied

by

the

manufacturer.

2. Do not use the saw in rain or on wet ground.

This tool is only intended for home use,

indoors.

1. Connect this tool to a 10 A, 230 V power supply circuit with a 10 A time delay fuse or circuit breaker.

The use of a fuse with the incorrect amperage could damage the motor.

2. If the motor does not start, immediately release the trigger. UNPLUG THE TOOL. Check the the blade runs

freely. If this is the case try to start the motor again. If the motor still does not start, refer to the “Motor

Troubleshooting table"

3. If the motor suddenly locks when cutting wood, release the trigger, unplug the tool and remove the blade from

the wood. Then try to restart the motor and finish the cut.

4. The fuse may "melt" or the circuit breaker trip if:

a.

The motor is overloaded - there is overload hazard in cases of too rapid advancement, or of stopping and

starting too frequently in a short period of time.

b.

A voltage up to 10% maximum higher or lower than that indicated on the nameplate can withstand normal

loads. In case of heavy loads, however, the voltage (due to a wire whose gauge is too small or one that is

too long in the power supply circuit) may fall to the point of not allowing the motor to function. Always

check the connections, the load and the power supply circuit if the motor malfunctions. Check the wire

gauges and lengths in the Wire gauge table below.

5. Most problems with the motor can be attributed to incorrect or loose connections, overload, insufficient voltage

(due, for example, to a wire with too small a gauge in the power supply circuit) or a wire that is too long in the

power supply circuit. Always check the connections, the load and the power supply circuit if the motor

malfunctions. Check the wire gauges and lengths in the Wire gauge table below.

Wire gauges

Use of an extension lead results in a loss of power. To minimise and avoid overheating and motor breakdown of

the motor determine the minimum gauge (the cross section) of the extension lead wires using the table below. For

circuits more than 40 m away from the power supply cabinet, the gauge of the wires should be proportionately

increased, in order to deliver sufficient voltage to the saw motor.

Cable Length

Wire gauge recommended for 230V.

Up to 15 m

1,5 mm²

15 to 40 m

2,5 mm²

15

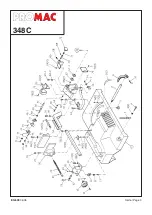

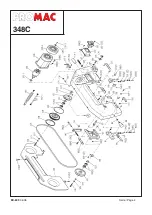

Summary of Contents for 348C

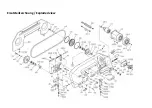

Page 22: ...Ersatzteilzeichnung Exploded view...

Page 23: ...Ersatzteilzeichnung Exploded view...

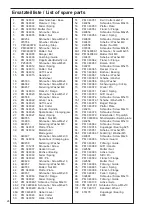

Page 29: ...Seite Page 3 EX 609 06 05 348C...

Page 30: ...Seite Page 4 EX 609 06 05 348C...