Section 16: SUPPLEMENT INFORMATION ON INDEPENDENT FRONT SUSPENSION (IFS)

16-28

2. Torque bushing collar nuts to 70 - 80 lbf•ft

(95 - 110 N•m).

3. Torque sway bar link upper nuts to 215 - 225

lbf•ft (290 - 305 N•m) and lower nuts to 70 - 80

lbf•ft (95 - 110 N•m).

7.2 Sway Bar (Drive Axle)

7.2.1 Removal

1. Disconnect the two links from sway bar.

2. Safely support the sway bar. Unbolt the four

bushing collars from subframe.

3. Remove sway bar.

Note:

Sway bar bushings are slitted to ease their

removal.

7.2.2 Installation

1. Loosely install the sway bar.

2. Torque the eight bushing collar nuts to 70 - 80

lbf•ft (95 - 110 N•m).

3. Torque sway bar link upper nuts to 215 - 230

lbf•ft (290 - 305 N•m) and lower nuts to 70 - 80

lbf•ft (95 - 110 N•m).

8. INDEPENDENT FRONT

SUSPENSION ADJUSTMENT

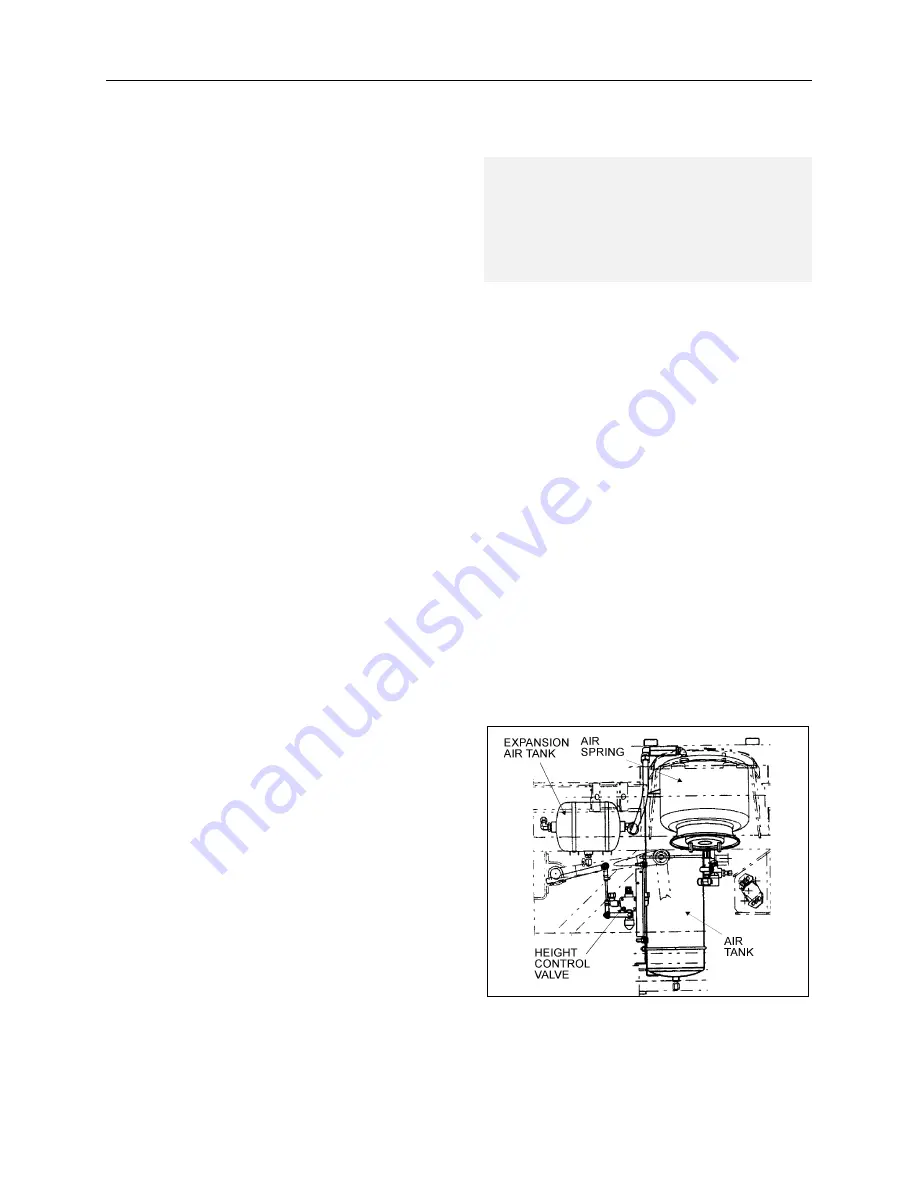

Converted coach shell is equipped with "LEVEL-

LOW" leveling system. The purpose of the

"LEVEL-LOW" is to adjust suspension in three

separate points (front, rear right and rear left air

springs) in order to level vehicle body. Three

height control valves, automatically control air

pressure in the three separate points (air springs)

and maintains a constant vehicle height regard-

less of load, or load distribution. The control sole-

noid valve supplies air to the five way three-

position air control valve, which bypasses the

height control valve, and opens a passage to

allow the air control and exhaust valve to re-

lease/supply air from airs springs. To improve

road comfort, an expansion air tank is installed in

series with each air springs.

In addition to the above suspension components

the system also includes : sway bar, upper and

lower suspensions, bars and shock absorbers

(Fig. 1).

Note:

Only for preliminary adjustment, refer to

figure 15. Torque rod length must be fixed to 23

9/64" (588 mm) and relay rod to 22 13/32"

(569 mm).

Caution :

Parts must be replaced by ones with

the same part numbers or with equivalent parts,

if replacement becomes necessary. Do not use

parts of lesser quality or substitute design.

Torque values must be used as specified during

reassembly to assure proper retention of these

parts.

8.1 Suspension Height

Adjustment

The flow of pressurized air from the accessory air

tank to the air springs is controlled by three height

control valves. The two rear valves are mounted

to the subframe and connected to the rear axles

through an arm and link connection. The front

valve is mounted to the subframe and connected

to the front air tank support (Fig. 22). These con-

nections allow the valves to apportion air pressure

in the springs to the vehicle load, maintaining

normal ride height.

Immediate response height control valves in-

crease or decrease the air pressure in the sus-

pension system as required. One height control

valve is located at center of front sway bar, and

regulates air to front suspension air springs in

order to maintain the vehicle at the required

height. Two are located at the drive axle, one on

each inner side of rear wheelhousing.

FIGURE 22: HEIGHT CONTROL VALVE LOCATION

16057