7

through the parameters using the arrow keys. Pressing the down arrow

scrolls to the next parameter in the list. Some parameters you can change;

others are view only. When a changeable parameter is at the top of the

screen, it is identified by an underline immediately to the right of its value.

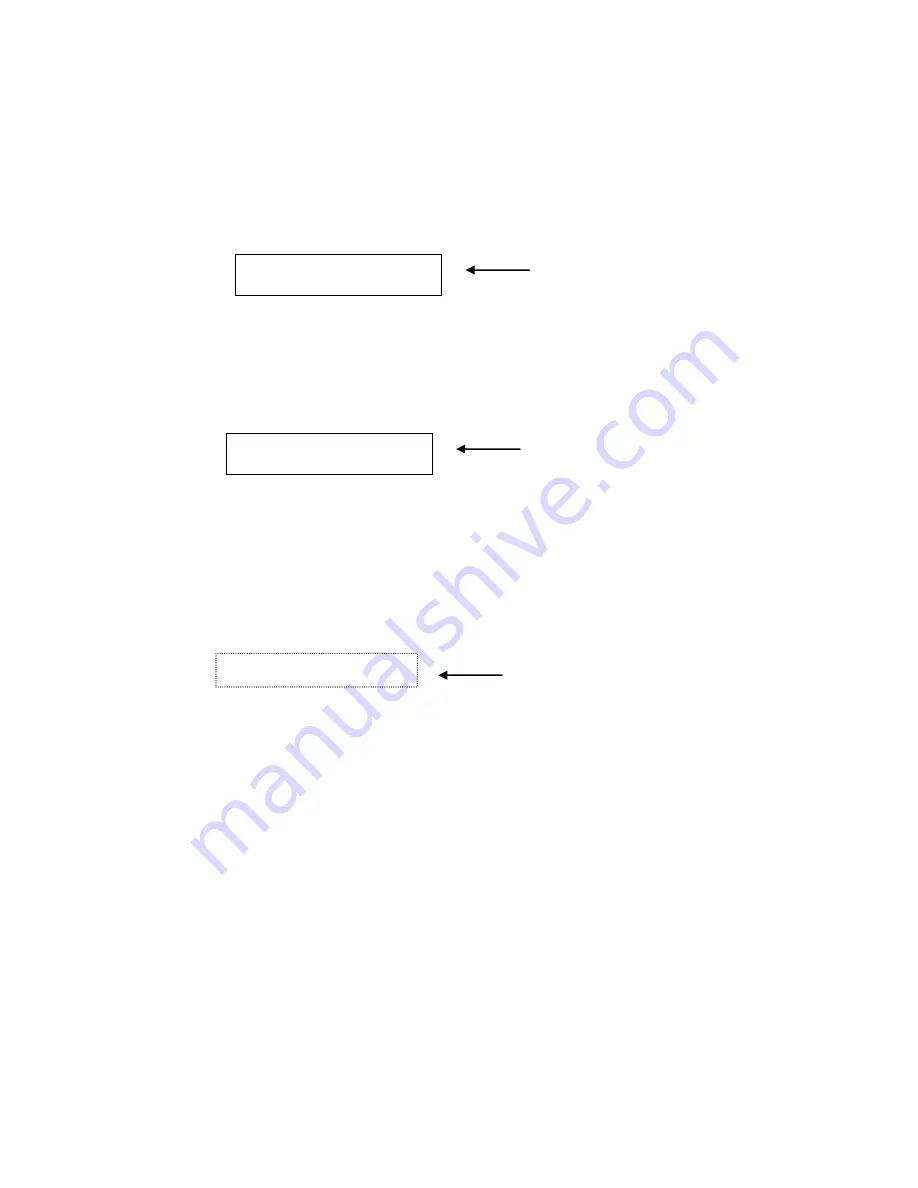

Figure 2 shows example.

Figure 2 Underline shows editable field

To change a parameter press the Enter key, the underline changes to a

block. You then use the arrow keys to adjust the parameter.

Figure 3 Up and down arrows change value

After changes, press the Enter key which returns you to the scroll mode.

Figure 4 Display shows window into parameters

While in scroll mode pressing the Menu key returns you to the General

Operation screen. Pressing the Play key starts the unit and returns you to

the General Operation screen.

TEMP LOW

10_

TEMP HIGH

90

Underline after value

denotes an editable

value

TEMP LOW

10

TEMP HIGH

90

Solid block after value

shows up and down

arrow can change value

VERSION

2.01

BELT ODO

3777 FT

TEMP LOW

0

TEMP HIGH

100

AIR LOW

20

AIR HIGH

100

SPEED

100

START DELAY

55

AIR OFFSET 100 MS

BIN SENSOR

OFF

SENSOR DELAY

1 S

UNITS

ENGLISH

LANGUAGE

ENGLISH

Display shows two lines.

Use up and down

arrows to move.