26

Copyright © 2020 Quality Machine Tools, LLC

PM-1228VF v3 2020-10

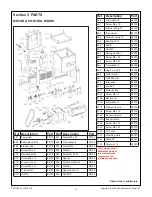

ADJUSTMENT — SPINDLE BEARINGS

The spindle runs on two grease-packed precision bearings,

a tapered roller bearing at the nose, and a deep-groove ball

bearing at the pulley end. They are factory adjusted, and

should need no attention. If end play becomes evident (work

-

piece chatter, poor finish, etc.), this can be corrected by tight

-

ening the spindle locknut, Figure 4-12. To do this, loosen the

two clamp screws, proceed as follows:

The item numbers refer to Figure 4-16 and also the Headstock

parts diagram

1. Remove the chuck or other work holding device from the

spindle.

2. Disengage the external gear train and remove the Vee belt.

3.

Using a 3 mm hex key, remove the two flat-head screws,

item #251 (removing the screws allows the compressible

locknut #281 to turn).

4. Unscrew locknut #281 one full turn.

5.

Place a scrap wooden block about 3/4″ thick over the left

hand end of the spindle.

6. Strike the block with a heavy dead-blow hammer. The in-

tention is to drive the spindle forward just enough to intro-

duce end float detectable by hand.

7. Using the supplied pin wrench located in the arrowed holes,

Figure 4-16), re-tighten the locknut to the point where the

spindle rotates (by hand) with noticeable resistance.

8.

Back off the nut a few degrees then check spindle rotation

again.

9. Re-loosen and re-tighten a few times to achieve the best

compromise, then re-compress the locknut with the two

flat-head screws.

10. Re-attach the Vee belt. Run the motor for a few seconds to

check for smooth/quiet operation.

11. Run the motor for a lengthy period, say 15 minutes, then

check the temperature of the spindle nose. It should be just

warm to the touch, no hotter than that.

If hotter than the “just warm” spec, the bearings are too heavily

pre-loaded. Back off the spindle locknut, then repeat the 15

minute temperature test..

ADJUSTMENT — LEADSCREW END FLOAT

ADJUSTMENT — LEADSCREW SPLIT-NUT

Figure 4-14

Split-nut adjustment

M5 socket head cap screws, 8 mm locknuts

Upper and lower split nuts run in vertical dovetails in the apron,

see part(s) #605 in the Apron parts diagram. The split-nut le

-

ver at the front of the apron should move smoothly, but with

a small degree of resistance. If is becomes noticeably loos-

er over time, this can be corrected by tightening the screws

shown in Figure 4-14.

Adjust the leadscrew and feed shaft for minimal end float (side

to side movement) without noticeable binding. Loosen the out

-

er locknut; tighten the inner nut to press the flat washer firmly

against the support bracket, then back off about 45 degrees.

Re-tighten the locknut .

19 mm

17 mm

Figure 4-15

End float adjustment

Figure 4-16

Pin wrench for spindle locknut

The inside rim of the wrench may need easing with a file or grinder

Screw

#251

Locknut

#281