P

RO

V

U

™ PD6088/PD6089 Modbus

®

Scanner

Instruction Manual

37

Parameter

PD6088

Master

PD6088

Snooper

Description/

Comment

PV12

Slave ID

4

4

Function

Code

04

04

Register

PV12

30017

30017

Tank 4

Average

Temperature

Data Type

Long

integer

Binary,

Signed

Long

Byte Order

1234

1234

Scanner

ID

246

245

Polling

Time

5.0 sec

N/A

Slave

Response

Timeout

10.0 sec

10.0 sec

Baud

4800

4800

Parity

None 1

None 1

1 stop bit

Byte-to-

Byte

Timeout

0.01 sec

0.01 sec

Decimal

point

3 places

3 places

Input 1

000000

000000

Scaling for

Level &

Interface

Display 1

000000

000000

Input 2

999999

999999

0.001 inch

resolution

Display 2

83.333

83.333

Feet

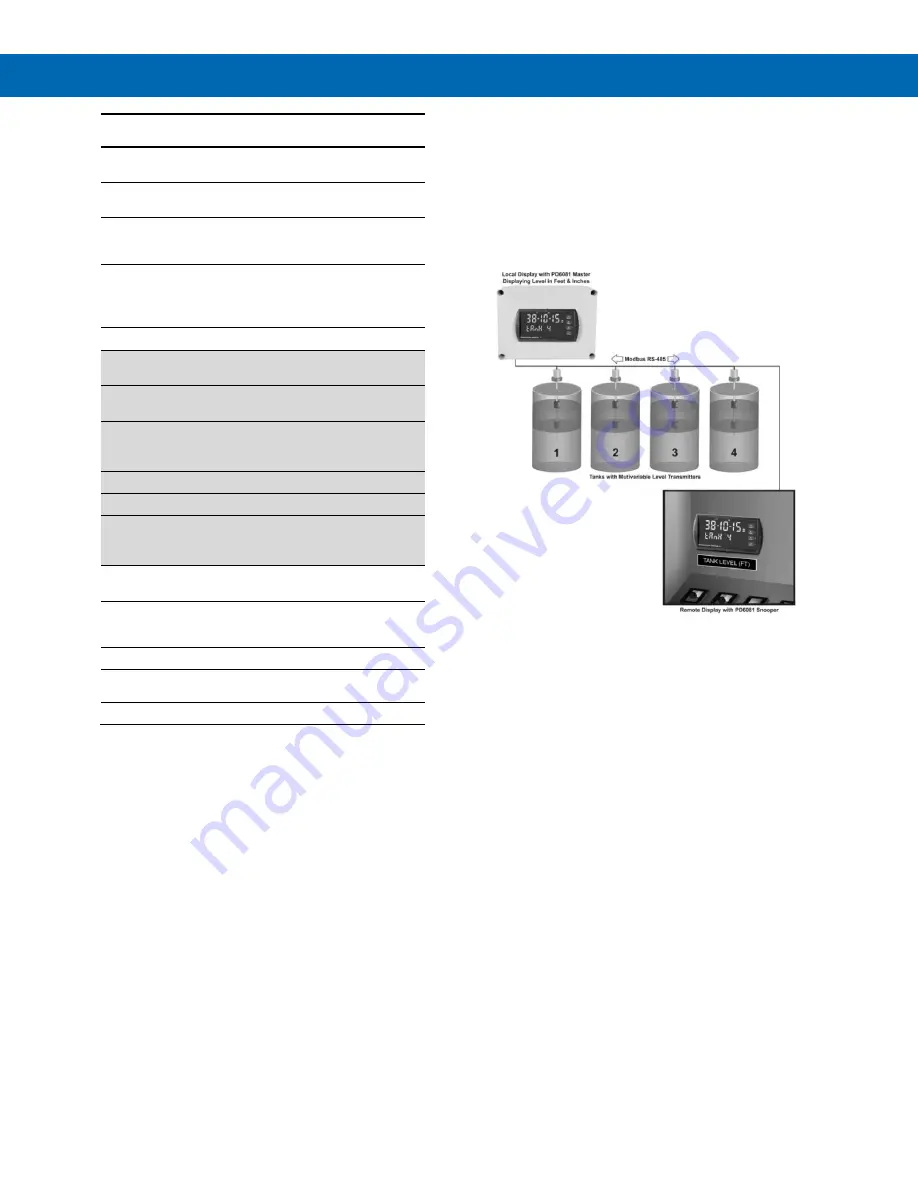

Application Example 2

In this application we have a system consisting of (4)

multivariable tank level gauges connected to (2)

PD6089s displaying Product Level, Interface Level,

and Average Temperature.

One of the Modbus Scanners is located next to the

tanks and the other is located in the control room. The

display readout is shown in sixteenths of an inch.

Register Numbers & Process

Variables

30001 - Product Level

30003 - Interface Level

30017 - Average Temperature

Note: The example above shows the PD6089.

The setup of the scanner is the same as

the first example. The PD6089

’s Feet &

Inches display is clearly visible.