prepASH Operating Instructions

Precisa

Ref01.i

9

4 Commissioning

4.1 Unpacking

Observe the following points when you unpack the ashing device in order to avoid damage:

•

Check the ashing device for any external visible signs of damage immediately after you

unpack it. If you find that it has been damaged in transit, notify your Precisa service agent

immediately.

•

Read these Operating Instructions carefully before starting to work with the ashing device and

pay particular attention to the safety instructions (see section 2 "Safety" on page

Fehler!

Textmarke nicht definiert.

).

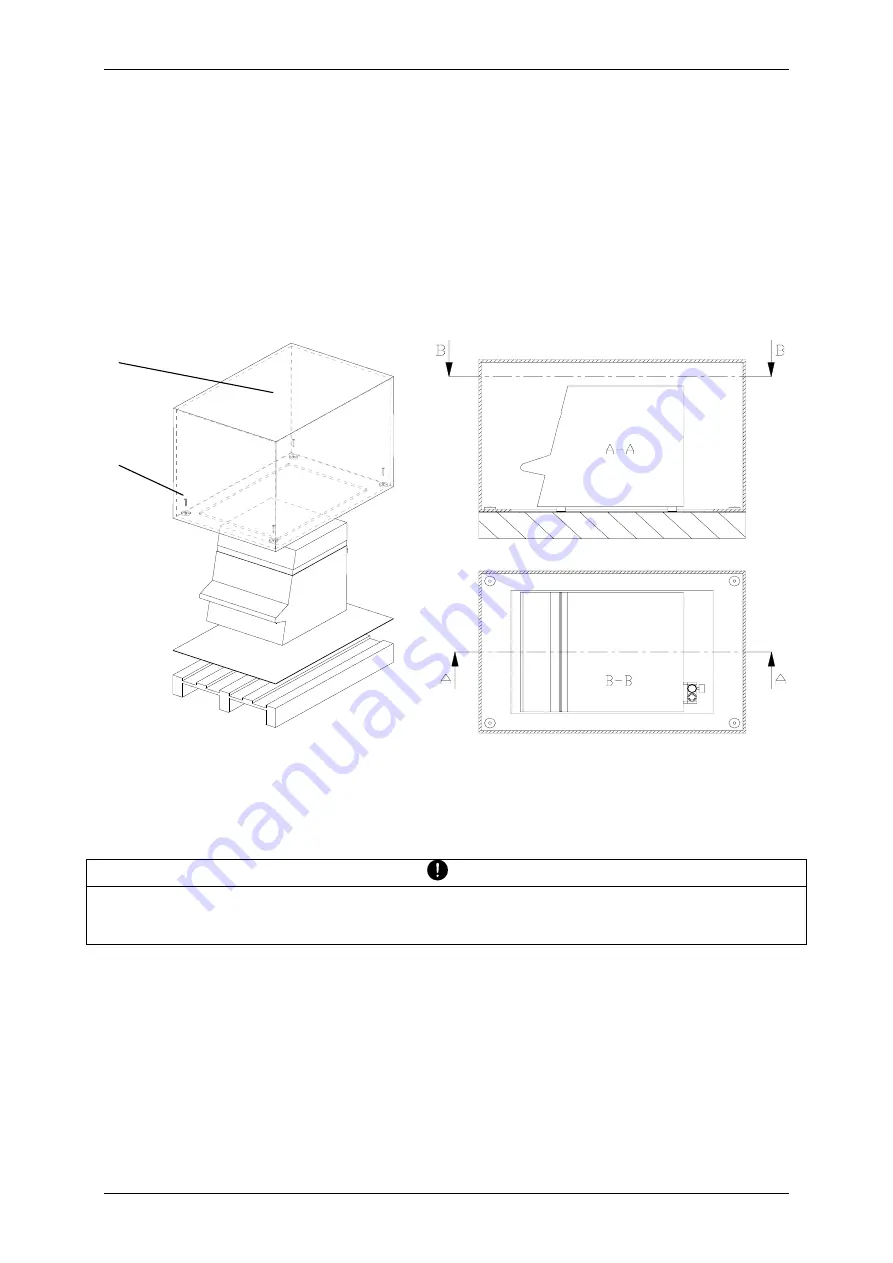

1

2

Unpacking the prepASH

1. Open the box (1) at the top

2. Remove all the padding and accessories

3. Undo the 4 screws (2) on the base of the cardboard box

4. Lift off the cardboard box

NOTE

Retain the packaging. If the device is delivered to the factory by a transport firm for repair after a

lengthy period of use, this may only be done in the original packaging. If devices are not properly

packaged, they may sustain considerable damage in transit.