10

Read and understand the entire

contents of this manual before attempting set-

up or operation. Failure to comply may cause

serious injury.

NOTE: Figures in this manual may show the lathe

with optional accessories, which are purchased

separately.

6.0

Setup and Assembly

6.1

Unpacking

Open shipping container and check for shipping

damage. Report any damage immediately to your

distributor and shipping agent. Do not discard any

shipping material until the Lathe is assembled and

running properly.

Compare the contents of your container with the

following parts list to make sure all parts are intact.

Missing parts, if any, should be reported to your

distributor. Read the instruction manual thoroughly

for assembly, maintenance and safety instructions.

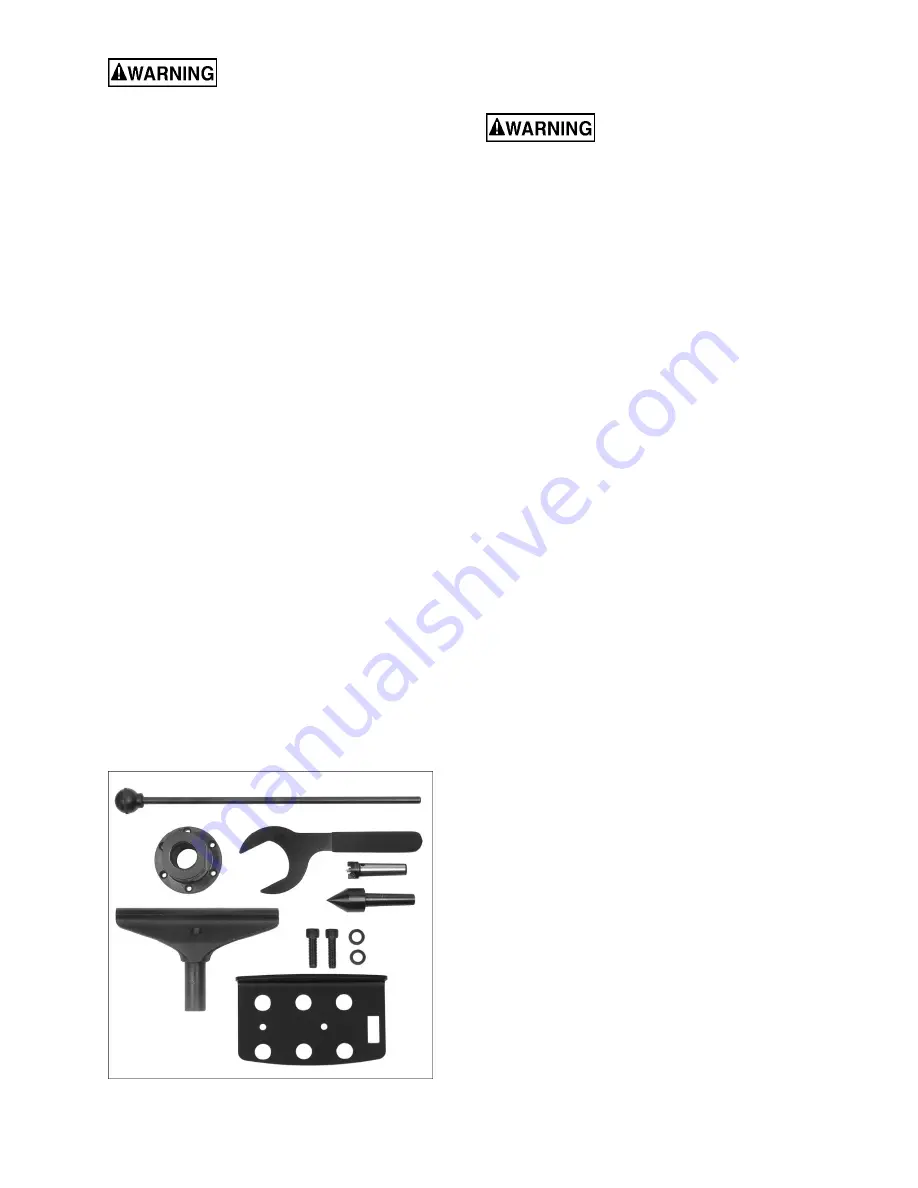

6.2

Contents of shipping container

See Figure 6-1.

1 Lathe with headstock, tailstock, and tool rest

base (not shown)

1 Knockout

rod

1 Face plate 3in.

1 Face

plate

wrench

1 Toolrest, 8in.

1 Spur center 1in.

1 Cone live center

2 Socket head cap screws, 3/8 x 1-1/4

2 Flat washers, 3/8

1 Tool

caddy

1 Owner's manual (not shown)

1 Product registration card (not shown)

Figure 6-1: accessories included

6.3

Tools required for assembly

8mm hex key (“Allen wrench”)

The Lathe must be discon-

nected from power during assembly. Use an

assistant or a hoist to help lift items.

1. Remove any screws or straps that hold the

Lathe parts to the pallet, and remove protective

wrapping. Set all boxes containing accessories

to the side.

2. The Lathe should be located in a dry area, on a

sturdy bench or the Powermatic accessory

stand (#1792014S), and with sufficient lighting.

Leave plenty of space around the machine for

operations and routine maintenance work.

(If the accessory stand was purchased, refer to

the assembly instructions that accompany it.)

3. Exposed metal areas of the Lathe, such as bed

ways and spindles, have been factory coated

with a protectant. This should be removed with

a soft cloth and a cleaner-degreaser. Clean the

bed areas under headstock, tailstock and tool

support base. Do not use an abrasive pad, and

do not allow solvents to contact painted or

plastic areas.

4. Apply a light coat of SAE10 oil to the exposed

metal areas to impede rust.

6.4

Tool caddy

The tool caddy may be mounted to the lathe bed

with the provided screws and washers. See Figure

5-1.

6.5

#6294755 Bed extension

(OPTIONAL)

If you did not purchase the optional 13-inch bed

extension, proceed to sect. 6.6.

To mount bed extension to Lathe:

1. Slide tailstock away from edge of bed, and

unscrew stud (A, Figure 6-2).

2. Have an assistant hold bed extension flush to

end of Lathe bed, and insert four 3/8 x 1-3/4

socket head cap screws with lock washers and

flat washers (provided with extension bed)

through holes in bed extension into threaded

holes on Lathe (8mm hex wrench). Make

screws snug but do not fully tighten. See Figure

6-2.

3. Adjust extension bed to lathe bed, aligning top

surface and inside ways as closely as possible.

Make screws snug but

do not fully tighten yet

.

4. Slide tailstock over joint where beds meet, so

that clamping nut is centered over joint, as

shown in Figure 6-2. Firmly tighten tailstock

clamping handle; this will align the beds.

Summary of Contents for PM2014

Page 27: ...27 15 1 1 PM2014 Headstock Assembly Exploded View ...

Page 30: ...30 15 2 1 PM2014 Bed Toolrest and Tailstock Assemblies Exploded View ...

Page 35: ...35 16 0 Electrical connections PM2014 Lathe cont next page ...

Page 36: ...36 cont ...

Page 38: ...38 This page intentionally left blank ...

Page 39: ...39 This page intentionally left blank ...

Page 40: ...40 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www powermatic com ...