25

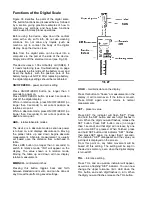

Press TOL button once (no longer than 1 second)

and that digit will increase each time TOL is

pressed.

When finished, press and hold TOL button until

indicator “SET” flashes. While indicator “SET” is

flashing, press SET button to change the arrow to

the down-arrow indicator. You can now change the

lower tolerance limit in the same manner as you

changed the upper tolerance limit.

When finished setting the lower tolerance limit,

while indicator “SET” is flashing, press SET button

(no longer than 1 second). The device is now in

tolerance measuring mode. When the up-arrow

indicator is displayed, it means the measured

value is beyond the upper limit. When the down-

arrow indicator is displayed, the measured value is

below the lower limit. When the display shows an

“OK” indicator, the measured value is within

tolerance.

Calibrating & Using Digital Scale

Scale Alignment

The scale assembly has been mounted and

aligned with the 15S Planer table at the factory.

The scale should be in vertical position, and the

digital device should slide smoothly along the full

length of the scale. Check occasionally that the

screws holding the device to the planer are tight. If

any realignment of the scale should ever be

needed, slots are provided in the mounting

brackets (Fig. 40).

Establish Absolute Zero

One of your first steps should be to “zero” the

digital scale in absolute mode. This is equivalent to

finding the exact point of contact between the

cutterhead knife and the table. This can’t be done

simply by raising the table, because the depth

limiter on the head casting will prevent contact

between table and cutterhead. However, there are

two relatively easy methods of establishing zero in

absolute mode:

Method 1 uses a gauge, such as a height gauge,

or a home-made gauge block (see Fig. 17). If

using a home-made gauge block, make sure it has

been cut to exact specifications.

1. Disconnect machine from power source.

2. Turn on the digital display. It turns on in

absolute mode.

3. Place the gauge upon the planer table and

under the cutterhead. (Make sure the gauge

lies solidly upon the table and not upon the

table rollers.)

4. Raise the table until the gauge just touches the

lowest point of a knife. Rock the cutterhead

slightly (use the pulley to do this) to make

certain the knife’s high point is contacting the

gauge.

5. The reading on the gauge, or the height of the

gauge block, should now be input into the

digital display. Refer to the instructions above

involving the “SET” button function to input

this number into your digital display.

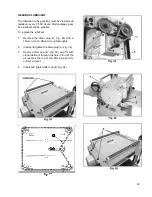

Method 2 uses a scrap board and calipers.

1. Turn on the digital display. It turns on in

absolute mode.

2. Plane one side of a scrap board at an

appropriate and safe cutting depth (1/16” for

example).

3. Raise the table by the same amount (1/16”),

then turn the board over and plane the other

side. Do not move the table from the current

position.

4. Measure the planed board carefully with

calipers. (Our example in Fig. 41 shows the

calipers reading .850”). This measurement of

the finished board is the equivalent of the

distance from table to knife.

6. Input the measurement on the calipers into the

digital display. Refer to the instructions above

involving the SET button function to input this

number into your digital display. (Fig. 41 shows

the .850” measurement now set in the digital

display.)

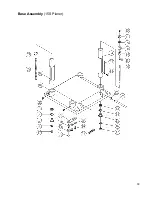

Summary of Contents for 15S

Page 7: ...7 FEATURES 15S Planer Fig 2 ...

Page 33: ...33 Base Assembly 15S Planer ...

Page 35: ...35 Table Assembly 15S Planer ...

Page 37: ...37 Gearbox Assembly 15S Planer ...

Page 39: ...39 Cabinet Assembly 15S Planer ...

Page 42: ...42 Head Assembly 15S Planer ...

Page 43: ...43 ELECTRICAL SCHEMATIC 15S Planer Single phase 230 volt ...

Page 44: ...44 ...

Page 46: ...46 ...

Page 47: ...47 ...