13

ADJUSTMENTS

Tools required

3, 5 and 6mm hex wrenches

10, 12 and 17mm open-end wrenches

0.2” (0.5mm) feeler gauge

straight edge

gauge block

cross-point screwdriver

WARNING: Disconnect machine from

power source before making any

adjustments (except feed rate).

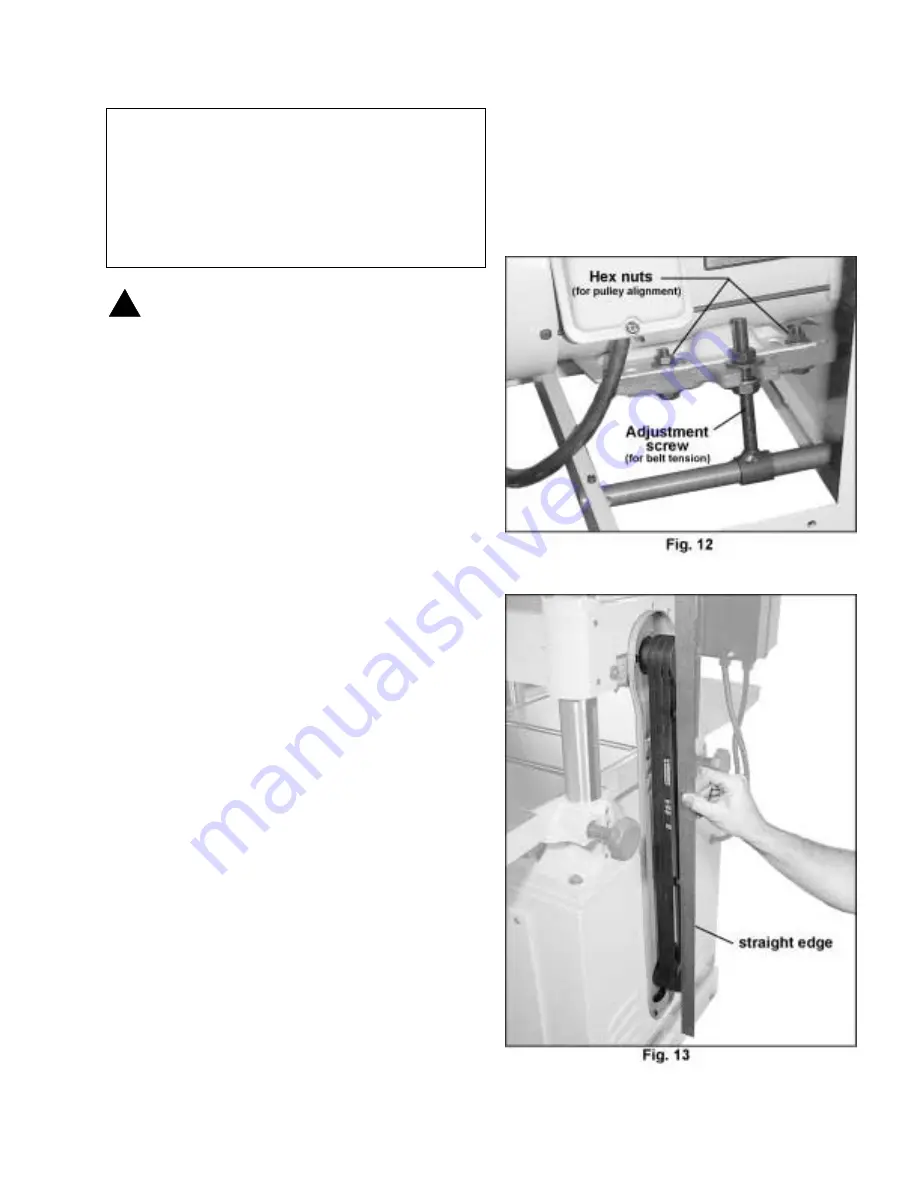

BELT TENSION

Inspect the tension of the belts frequently during

the first few times you use the planer. Belts often

stretch during this trial period. If they require

tightening, proceed as follows:

1.

Remove the belt guard and the rear panel.

2. Loosen the bottom nut on the motor

adjustment screw (Fig. 12) with a 17mm

wrench.

3.

Turn the top nut on the adjustment screw to

lower the motor plate, which will increase the

belt tension.

4. Proper tension is achieved when there is

slight deflection in the belt midway between

the pulleys, using moderate finger pressure.

5. Tighten the bottom nut on the adjustment

screw (Fig. 12).

PULLEY ALIGNMENT

The pulleys should be in line for proper belt

operation.

1.

Remove the belt guard and place a straight

edge against the faces of both pulleys (Fig.

13).

2.

If the straight edge does not lie flat on both

pulley faces, open the rear panel and loosen

the four hex nuts on the motor plate (see

Fig. 12) with a 12mm wrench.

3.

Nudge the motor left or right until the pulleys

are in alignment.

4.

Tighten hex nuts and replace covers.

!

Summary of Contents for 15S

Page 7: ...7 FEATURES 15S Planer Fig 2 ...

Page 33: ...33 Base Assembly 15S Planer ...

Page 35: ...35 Table Assembly 15S Planer ...

Page 37: ...37 Gearbox Assembly 15S Planer ...

Page 39: ...39 Cabinet Assembly 15S Planer ...

Page 42: ...42 Head Assembly 15S Planer ...

Page 43: ...43 ELECTRICAL SCHEMATIC 15S Planer Single phase 230 volt ...

Page 44: ...44 ...

Page 46: ...46 ...

Page 47: ...47 ...