8

ELECTRICAL CONNECTIONS

▲

WARNING: DO NOT APPLY POWER UNTIL TOLD TO DO SO!

RISK OF SHOCK OR INJURY MAY RESULT.

Before connecting the

operator, use a voltmeter to determine that the electrical service is 115

VAC. This operator cannot be connected to 220 volts. Damage will result,

which is NOT covered by warranty.

1.

▲

Be sure power switches at source and operator are OFF.

2.Connect incoming power lines and ground wire as follows:

Hot leg (black) to black; Neutral (white) to white; Ground to screw.

Note:

Wiring to operator must use watertight materials in accordance with

local electric code.

Note:

Master/Slave installation should have SEPARATE

power supply wiring. If sharing a power supply line,

obstruction sensing adjustments may require recalibration.

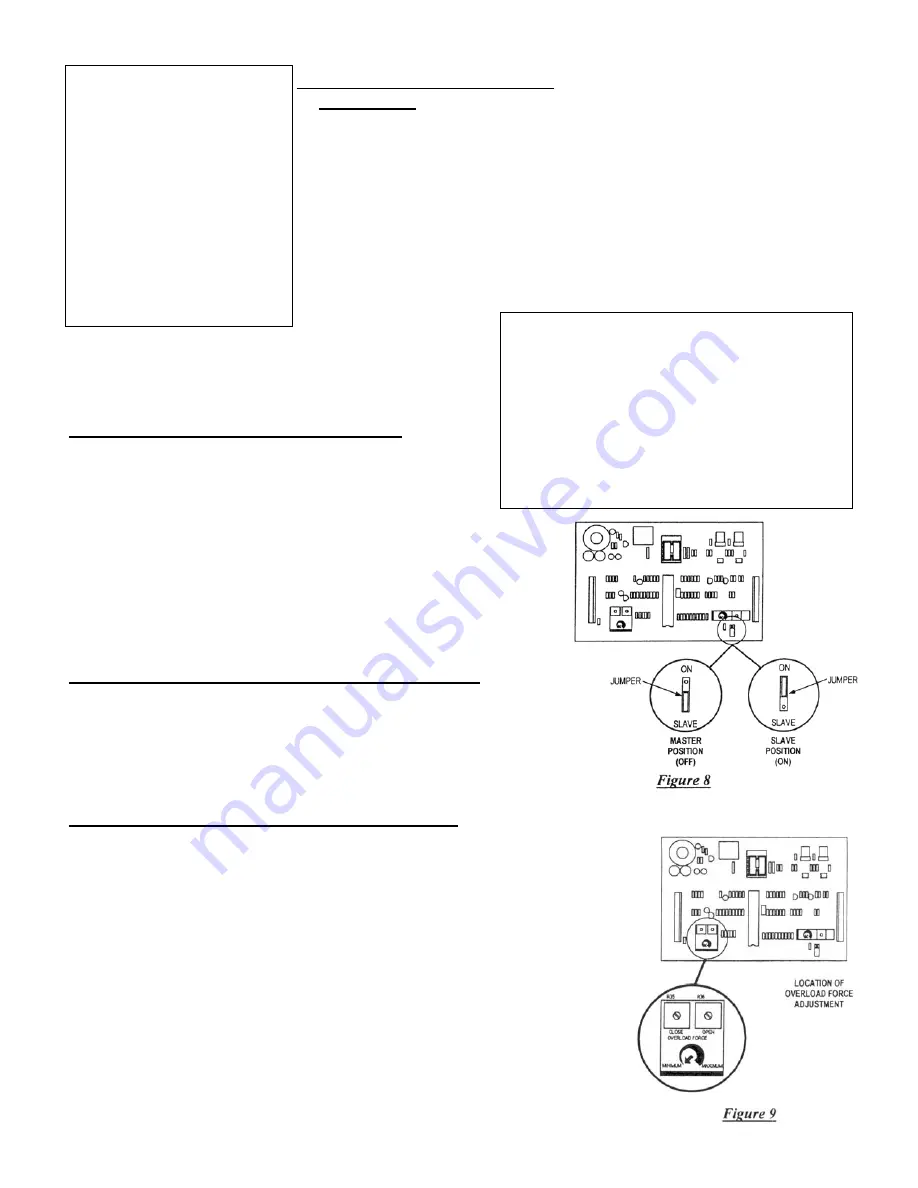

FOR MASTER/SLAVE INSTALLATION:

Note:

A single unit is considered Master.

1. Place jumper on the master operator's P.C. board in the

"OFF" position (See Fig. 8).

2. Place jumper on slave operator's P.C. board in the

"ON" position. (See Fig. 8).

3. Connect terminal # 15 of Master unit to terminal #5 of slave unit.

4. Connect terminal # 16 of Master unit to terminal #6 of slave unit.

5. Connect Terminal # 17 of Master unit to terminal #7 of slave

unit. Note: In Master/Slave installation, one unit must be

converted to LEFT HAND operation.

CONNECTION OF A THREE BUTTON STATION:

Note: All control contacts must be NORMALLY OPEN.

Connect "STOP" button to terminal #4

Connect "COMMON" button to terminal #5

Connect "OPEN" button to terminal #6

Connect "CLOSE" to terminal #7

PRIMARY OBSTRUCTION SENSING DEVICE:

Note:

Gate must move smoothly and easily in manual operation before

attempting this adjustment. This unit is supplied with a current sensing

system which will stop gate when activated and then back the gate off

approximately 2 inches and stop. If the gate is started again and the sensing

system is activated a second time before hitting a limit switch, the gate will

stop and sound a warning signal. A constant pressure control will then be

needed to start the gate. This sensing system has adjustments located on

printed circuit board (See Fig. 9). The force required to activate the system

may be adjusted in both OPEN and CLOSE direction separately. Start at

minimum force, and increase force until it is just over what is required to

move the gate smoothly without any nuisance tripping.

NEVER INCREASE FORCE SETTING TO MAKE UP FOR A GATE

THAT IS NOT MAINTAINED PROPERLY. THIS WILL

DESENSITIZE THE OPERATION OF THE SAFETY SYSTEM.

HIGH VOLTAGE

WIRE GAUGE/

DISTANCE CHART

16 AWG

Up to 200’

14 AWG

200’ to 500’

12 AWG

500’ to 900’

10 AWG

900’ to 1200’

Over 1200’ consult the factory

HIGH VOLTAGE WIRE GAUGE/

DISTANCE CHART

24 AWG

Up to 150’

20 AWG

150’ to 250’

18 AWG

500’ to 900’

Control wiring should be run as twisted pairs. Do not run

control wires in the same conduit as power wires,

telephone wires or loop detectors leads

Summary of Contents for RSG 2000

Page 13: ...13...