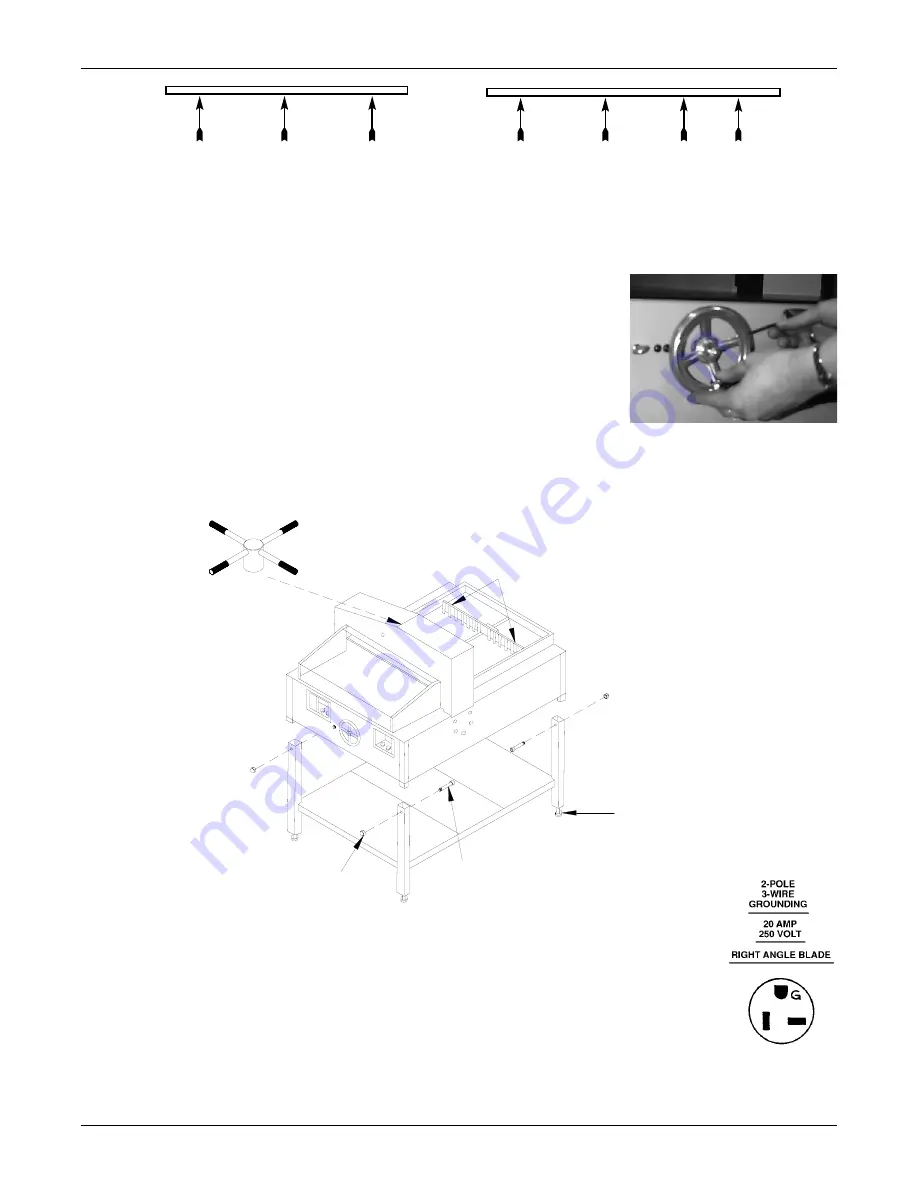

4.4 Installing the Handwheel

To help prevent shipping damage, the back gauge handwheel to your PowerLine cutter hasnot been installed. A 5/32" Hex

key wrench has been included so that the handwheel can be installed on the shaft that extends from the front center of the

machine. Two handwheel set screws must be securely tightened so that the handwheel will not freely turn on the shaft. To

install the handwheel:

1. Located the shaft that protrudes from the front center of the machine.

2. Slide the handwheel onto the shaft so that one of the set screws is aligned over the

flat surface on the shaft. Position the handwheel so that it will not rub against the

machine chassis. This is achieved when the end of the shaft is even with the outer

surface of the handwheel inner hub.

3. When the handwheel is properly positioned, securely tighten each set screw against

the shaft. You may use a commercial thread locking glue to secure the set screws in

place.

4.4 Separating the Stand and Chassis

To separate the chassis from the stand, remove the carriage bolt and acorn nut from the top of each stand leg. Lift the chas-

sis from the stand using a mechanical lifting device. To reassemble the stand and chassis, lower the chassis onto the stand

and install the carriage bolt and acorn nut through each stand leg.

4.5 Power Requirements

The electric cutter is equipped with a 20 Amp power plug (NEMA #6-20P). This cutter requires an 20

Amp circuit with a 20 Amp receptacle (NEMA #6-20R). Have a qualified electrician install the appro-

priate branch circuit and receptacle.

4.6 Optional Side Tables

To install the optional side tables, simply align the holes in the tables with the screw holes in the machine frame. Install and

tighten the provided screws.

PowerLine Operating Instructions

4

26" False Clamp Screw Location

21" False Clamp Screw Location

ACORN NUT (4)

CARRIAGE BOLT (4)

LEG LEVELER (4)

BACK GAUGE LOCKING SCREWS (2)