6

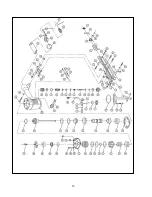

Refer to the Maintenance and Repairs sections for detailed information on the proper

maintenance of the tool.

Always operate the tool in a clean, lighted area.

Be sure the work surface is clear of any debris and be

careful not to lose footing when working in elevated environments such as rooftops.

Do not drive fasteners near edge of material.

The workpiece may split causing the fastener to ricochet,

injuring you or a co-worker. Be aware that the nail may follow the grain of the wood (shiner), causing it

to protrude unexpectedly from the side of the work material. Drive the nail perpendicular to the grain to

reduce risk of injury.

Do not drive nails onto the heads of other fasteners or with the tool at too steep an angle.

Personal

injury from strong recoil, jammed fasteners, or ricocheted nails may result.

Be aware of material thickness when using the nailer.

A protruding nail may cause injury.

Be aware that when the tool is being utilized at pressures on the high end of its operating range,

nails can be driven completely through thin or very soft work material.

Make sure the pressure in the

compressor is set so that nails are set into the material and not pushed completely through.

Keep hands and body parts clear of immediate work area.

Hold workpiece with clamps when

necessary to keep hands and body out of potential harm. Be sure the workpiece is properly secured before

pressing the nailer against the material. The contact trip may cause the work material to shift

unexpectedly.

Do not use tool in the presence of flammable dust, gases or fumes.

The tool may produce a spark that

could ignite gases causing a fire. Driving a nail into another nail may also cause a spark.

Keep face and body parts away from back of the tool cap when working in restricted areas.

Sudden

recoil can result in impact to the body, especially when nailing into hard or dense material.

Grip tool firmly to maintain control while allowing tool to recoil away from work surface as

fastener is driven.

With the contact trip (black) trigger assembled, if contact trip is allowed to recontact

work surface before trigger is released an unwanted fastener will be driven.

Choice of triggering is important.

Check the manual for triggering options. Refer to Trigger Operation

under the Operation section.

DEPTH ADJUSTMENT: To reduce risk of serious injury from accidental actuation when

attempting to adjust depth, ALWAYS:

•

Disconnect air supply.

•

Avoid contact with trigger during adjustments.

WARNING:

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California to cause cancer,

birth defects or other reproductive harm. Some examples of these chemicals are:

•

Lead from lead-based paints,

•

Crystalline silica from bricks and cement and other masonry products, and

•

Arsenic and chromium from chemically-treated lumber.