11

5.

Pull the trigger.

-If the nail drove into the wood for enough, continue with your intended operations.

-If the nail either went too far or not far enough, then refer to Adjusting Depth subsection.

WANRNING:

During operation, this nailer can propel objects into the air and exhaust

concentrated bursts of air, causing immediate

eye damage. To reduce your risk from these

hazards, always wear

ANSI approved safety galsses or a face shield.

WARNING:

Never point this nalier at yourself or another person! Always pay attention to

the direction this nailer is pointed to reduce the risk of serious injury.

Adjusting Depth

A depth adjustment device is attached to the nose for setting the nail depth.

To adjust the depth:

1.

Disconnect nailer from the air supply!

2.

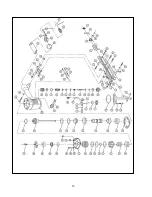

Loosen the cap screw on the depth adjustment device(Figure 3),

and move the safety nose backward to increase the nail depth or

forward to decrease the nail depth.

3.

Connect nailer to the air supply, test the nail depth, and repeat

this entire procedure if necessary until the nail depth is

satisfactory.

Clearing Jammed Nails

A jammed nail must be cleared before using the nailer again.

To clear a jammed nail from the discharge area:

1.

Disconnect nailer from the air supply!

2.

Pull the magazine handle all the way back until it latches.

3.

Remove the nail stick from the magazine.

4.

Locate the opening in the underside of the nailer nose (Figure 4).

5.

Dislodge the jammed nail with a tool that will fit in the slot on

the underside of the nose, such as needle nose pliers.

6.

Throw the damaged nail away and insert a new nail stick that

only contains clean, undamaged nails. DO NOT use dirty or damaged nails!

Cleaning

Use a good solvent to clean the nose assembly of the nailer. Always be sure that the nailer is dry before

using it again.

Do not allow dust, chips, sand, etc. into the air connectors or into the body of the nailer; this may result

in leaks and damage to the nailer and the air couplings.

WANRNING:

Never use gasoline or other flammable liquids to clean this tool. Vapors in the

tool may ignite, causing the tool to explode. Ignoring this warning may lead to serious

personal injury or even death!

Air supply

1.

Use clean, Dry and regulated compressed air at 80-120 PSI (5.5-8bar).

Fig.3

Fig.4